BobCAM for SolidWorks

BobCAM for SolidWorks

BobCAD-CAM software has released their BobCAM for SolidWorks add-in for SolidWorks design software customers worldwide.

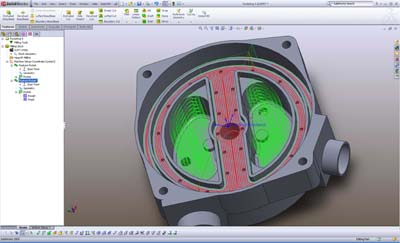

BobCAD-CAM software has released their BobCAM for SolidWorks add-in for SolidWorks design software customers worldwide. SolidWorks customers can now take advantage of the BobCAM automatic 2, 3 and 4th axis machining capabilities without having to use a separate CAM system for toolpath and G-Code programming for CNC machining. The primary benefit of BobCAM is that machining operations can be defined, calculated and verified without leaving the parametric SolidWorks design environment. All 2-, 3- and 4-axis machining features are fully associative to the part model. If you make any changes to your SolidWorks model, all your CAM operations are easily updated. Full associativity between the SolidWorks design and machining operations in the new CAM tree effectively reduces errors when the part model is changed. The user has the ability to create special tool patterns for hole drilling as well as any of the other machining strategies offered in BobCAM. These tool patterns and cutting conditions can be associated with the specific part being machined or used globally throughout the system. The user simply loads the machining feature, selects the model and BobCAM loads all of the depths and correct tools for the operation. Then the user can further customize the operations and automatically generate the toolpaths and G-code program for the machine of choice. BobCAM offers functionality for profiling, pocketing, engraving, plunge roughing as well as the more advanced 3-axis toolpaths, such as Z-Level roughing and finishing operations. BobCAM provides a material and tool database that can be customized as well as fully customizable post processors for CNC milling, routers, waterJet, laser and burning machines. BobCAM includes virtual toolpath simulation, RS 232 communications and DNC capabilities. BobCAM comes with a comprehensive built-in help system as well as user training manual.