A Brand AT-1 thread mills

A Brand AT-1 thread mills

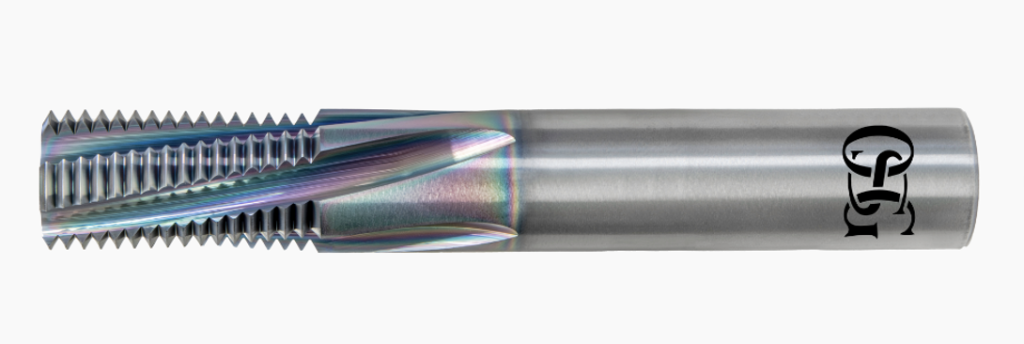

OSG USA Inc., St. Charles, Illinois, expands its A Brand Thread Mill series with the addition of the AT-1, an advanced performance one-pass thread mill suited for various materials.

OSG USA Inc., St. Charles, Illinois, expands its A Brand Thread Mill series with the addition of the AT-1, an advanced performance one-pass thread mill suited for various materials.

The 16632 thread mill features:

- EgiAs coating for superior wear resistance,

- a right-hand cut and left-hand helix geometry for increased tool stability,

- ultra-fine grain carbide for high wear resistance and toughness,

- unequal spacing and variable lead flute to reduce vibration.

View the OSG A Brand AT-1 product flyer for more information.