c-Si Module Production Lines

c-Si Module Production Lines

MAG is expanding its solar panel manufacturing systems business with the establishment of U.S.-based operations to build and distribute crystalline silicon (c-Si) module production lines with capacities up to 130 MWp.

MAG is expanding its solar panel manufacturing systems business with the establishment of U.S.-based operations to build and distribute crystalline silicon (c-Si) module production lines with capacities up to 130 MWp. In addition, the company's European operation continues its success in the market with receipt of an order for a 30-MW solar module production line from Solar-Energy sp. z o.o. in Poland, which will be built at MAG's facility in Schaffhausen, Switzerland.

"Solar installations in 2010 were up 100 percent over the previous year, despite the state of the overall economy," said Joe Jones, U.S. General Manager for MAG's renewable energy business unit. "Over the past five years, MAG has supplied more than 30 automated production lines for solar panels throughout the world, and our systems have reduced manufacturing costs for solar panels to record lows. Establishing manufacturing in the U.S. allows us to better serve the needs of the industry as it continues to expand."

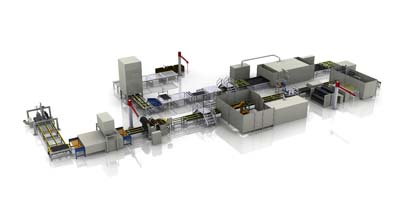

MAG provides solar manufacturing solutions ranging from semiautomatic modules to complete turnkey factories for panels that utilize a variety of materials technology. The turnkey c-Si lines are available fully automated or with manual-assisted solutions for lower output operations. As a robot-free solution, the lines are highly reliable and carry a low total cost of ownership (TCO), with cycle times as low as 40 seconds. Modular design allows for configuration of load/unload solutions, conveyance, storage and pack-out, as well as accommodating non-MAG equipment and turnkey controls integration. Backend solutions include trimming, taping, sealing, framing and junction box assembly. Testing and special solutions, such as interconnection soldering, are also available. The new 30-megawatt manufacturing line for Solar-Energy Sp. z o.o., Poland, will be built at MAG's Schaffhausen, Switzerland plant, the original site for MAG's solar operations.

This system will include all production steps for manufacturing photovoltaic modules, including glass loading, connecting cells and lamination, assembly of frames and junction box, testing and sorting. The manufacturing line will be located at the Solar-Energy facilities in Bozepole Wielkie, Poland, about 40 miles from Gdansk, and should be in operation as early as summer 2011. The company will market the PV modules in Eastern and Western Europe, and they will be appropriately certified.

"MAG's comprehensive expertise in design and development of automated production systems, coupled with its global support, played a great role in our selection of the company," said Zbigniew Kulik, President of Solar-Energy. He added that the system's high degree of automation would ensure highest production quality. "We continue to see strong activity in wind and solar manufacturing worldwide," said Jones. "Given the strong competition we have in Europe, this contract speaks volumes about our achievements in the market, particularly in global service support."