CAMWorks 2012

CAMWorks 2012

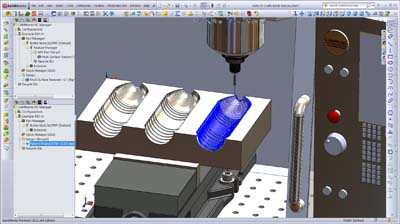

Geometric announced the release of CAMWorks 2012, its solids-based CNC programming solution.

Geometric announced the release of CAMWorks 2012, its solids-based CNC programming solution. The new release features support for SolidWorks 2012, as well as improvements to enable faster and easier programming and to produce more efficient tool paths for improved machining productivity.

Along with its benefits and support for SolidWorks 2012, the new release features: feature recognition performance and improvements; Version 4.0 of VoluMill with the new non-concentric milling technology that reduces cutting-tool loads and evacuates chips more efficiently; significant time reduction while saving files with large number of tool path moves; ability to add new tools into the TechDB from within CAMWorks; shaded display of "Contain" and "Avoid" areas; and turning roughing operations that support user-identified inserts.