Contact Details

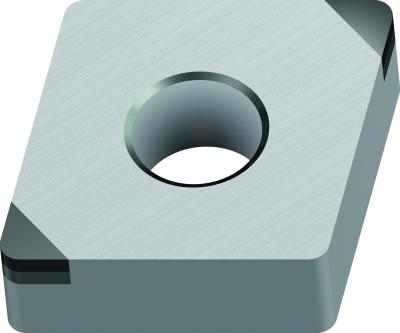

Walter has introduced the CBN grade WBH30 for hard turning in interrupted cuts. This new grade, with a reliable and high-performance substrate exhibits excellent toughness primarily because of its good distribution of mixed CBN grain sizes. In addition, the new grade offers chemical stability derived from a TiN binder that prevents crater and flank face wear. It also provides wear resistance in hardened steels due to the 65% CBN content, and higher feeds.

Additional improvement in surface quality and stability can be realized with advanced wiper geometry option. Walter offers the new WBH30 CBN grade in inserts with and without MW wiper geometry, and with a negative T-land chamfer for excellent strength in interrupted cuts.

WBH30 is the latest addition to the Walter family of CBN grades engineered to tackle the toughest machining challenges. These include grades WBH10C, WBH10, and WBH20 for turning of hardened steel up to 65 HRC. These grades provide users with benefits such as high-quality surface finish and long tool life. Walter has also created WBK20 and WBK30, CBN grades that bring higher levels of productivity and reliability to the machining of cast iron and certain specific applications in hardened steel, among other benefits.

Related Glossary Terms

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- hard turning

hard turning

Single-point cutting of a workpiece that has a hardness value higher than 45 HRC.

- titanium nitride ( TiN)

titanium nitride ( TiN)

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

Additional Products from Walter USA LLC

Pagination

- First page

- Previous page

- …

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

PRODUCTS

PRODUCTS