CL-1 Ultracompact CNC Chucker Lathe

CL-1 Ultracompact CNC Chucker Lathe

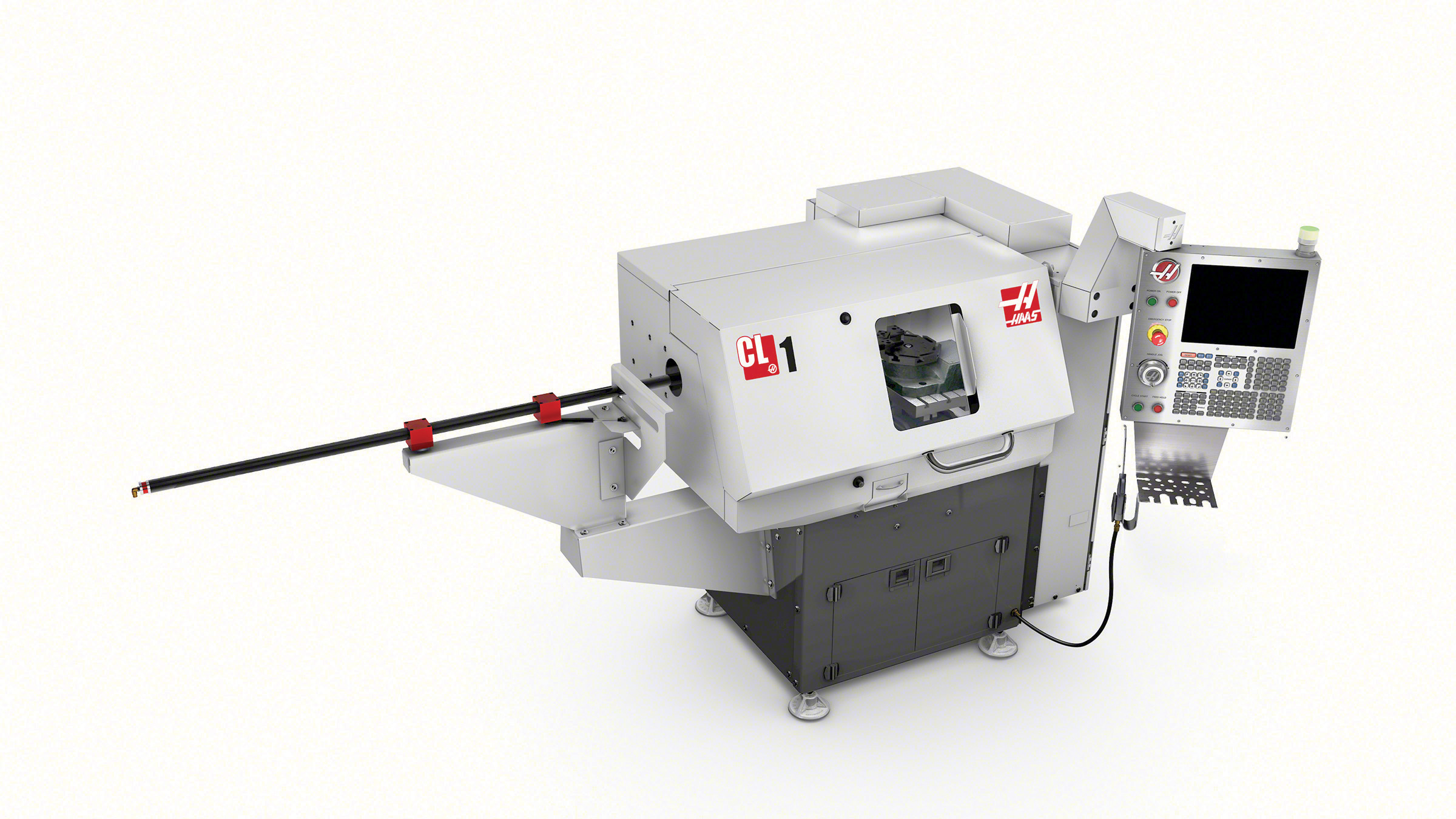

The CL-1 from Haas Automation Inc. is an ultracompact CNC chucker lathe that comes standard with an 8-station automatic turret, making it ideal for producing small, precision parts, such as those found in the communications, aerospace, medical and dental industries.

The CL-1 from Haas Automation Inc. is an ultracompact CNC chucker lathe that comes standard with an 8-station automatic turret, making it ideal for producing small, precision parts, such as those found in the communications, aerospace, medical and dental industries.

The CL-1 is equipped with a 5 hp (3.7 kW) spindle that turns to 6,000 rpm. The spindle's threaded 5C collet nose easily handles bar stock up to 1" (25.4 mm) in diameter, and features an automatic air-closer. For higher torque applications, an optional 8 hp (5.9 kW) 6,000-rpm spindle is available that provides double the torque of the standard spindle, as well as higher accel/decel rates. For longer production runs and unattended machining, an optional integrated pneumatic bar feeder and built-in parts catcher are available. The bar feeder automatically loads 0.25" to 1" (6.4 – 25.4 mm) diameter bars up to 1 meter long.

The CL-1's high-speed cross slide and servo-driven 8-station turret guarantee fast chip-to-chip times and short cycle times, while offering quick setup and good clearance. The turret uses gang-style tooling on 1/2" (13 mm) centers. Machine travels are 12" x 8" (305 x 203 mm) (x, z), and brushless servos on both axes yield cutting feeds to 500 ipm

(12.7 m/min) and rapids to 757 ipm (19.2 m/min). The user-friendly Haas control makes operation and set up simple.

Other standard equipment on the CL-1 includes a full C-axis, a coolant system, rigid tapping, a 15" color LCD monitor, and built-in USB connectivity. Available high-productivity options include Ethernet connectivity, a power-failure detection module, user-definable macros, expanded program memory, and more.

This ultracompact machine can be moved easily with a pallet jack or equipment dolly, and with its small size and light weight, the CL-1 also fits into most freight elevators. The machine runs on single-phase power (240 VAC).

For facilities needing milling capabilities as well as turning, Haas offers the equally diminutive CM-1 Compact Mill. The CM-1 features 12" x 10" x 12" (305 x 254 x 305 mm) travels, a 20" x 10" (508 x 254 mm) T-slot table, a Haas-designed and -built 30,000-rpm ISO 20-taper spindle, and a 20-pocket toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: automatic toolchanger">automatic toolchanger">automatic toolchanger.