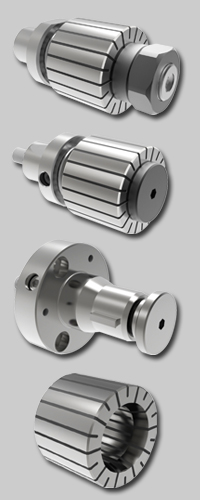

CNC Expanding Mandrels

CNC Expanding Mandrels

According to Royal Products, ID gripping is often overlooked as a workholding option, yet in many situations it is the best choice. For example, it allows for access to the entire length of the workpiece so all external surfaces can be turned in a single operation, ensuring perfect concentricity.

According to Royal Products, ID gripping is often overlooked as a workholding option, yet in many situations it is the best choice.

It allows for access to the entire length of the workpiece so all external surfaces can be turned in a single operation, ensuring perfect concentricity.

On subspindle machines, ID gripping on the second spindle eliminates the risk of surface damage that can be caused by second-op OD gripping on a previously turned diameter.

For many parts, the engagement length of an ID bore can be greater than what is available for OD gripping, resulting in superior rigidity and torque transmission.

ID systems tend to be more streamlined than OD systems, enabling better part access, which is especially important on machines with live tooling.