Connection With Siemens’ Teamcenter Software as Part of VERICUT

Connection With Siemens’ Teamcenter Software as Part of VERICUT

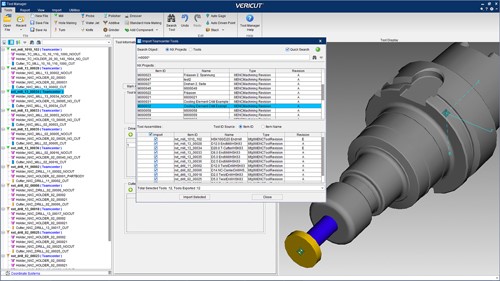

Using multiple software systems to manage cutting tool data and toolholder assembly models is both time-consuming and error-prone. That's why software developer CGTech announces that it offers a connection with Siemens' Teamcenter software as part of its toolpath simulation software, VERICUT.

Using multiple software systems to manage cutting tool data and toolholder assembly models is both time-consuming and error-prone. That's why software developer CGTech announces that it offers a connection with Siemens' Teamcenter software as part of its toolpath simulation software, VERICUT.

Current and future CGTech customers can enjoy seamless integration with the same technology that companies around the world depend on every day to enhance product development decision making and produce better products.

Siemens PLM Software is a leading global provider of product lifecycle management (PLM) software and services. Its Teamcenter portfolio, a popular digital lifecycle management software, is used widely across the aerospace, automotive, medical and other industries. Its NX software, is a leading integrated solution for computer-aided design, manufacturing and engineering (CAD/CAM/CAE).

NX users can click, connect and import files directly from NX, saving time and eliminating problems. "Oftentimes, the most labor-intensive part of toolpath verification is modeling the various cutting tools and assemblies," says Jeff Voegele, VERICUT product specialist at CGTech. "This is especially true with the large, complex machining work common with NX users, where 30 to 40 tools in a single job is not unusual. Because we now connect directly to Teamcenter, it's easy to search for individual tools within the PLM system or NX project files, and then read them into VERICUT accordingly, either individually or as a group. It's a huge timesaver."

The Teamcenter integration works seamlessly with MRL, explains Voegele. Users won't be tempted to model toolholder assemblies that are 'close enough' in an effort to save time, or be concerned about different models floating around outside the PLM system—versions are in control, and there is a commonality and standardization for all of a shop's cutting tools.

Also, VERICUT customers migrating their CAM systems to NX and Teamcenter can use their existing models, importing them directly into Teamcenter, or download them from such sources as Tools United, Machining Cloud or the tool vendor's website, thus creating a master library within the PLM system and one version of the truth.

"Siemens PLM Software is enthusiastic about the collaboration with CGTech. This agreement is another important step in the development of an integrated solution that will provide added value to our mutual customers," says Corsin Buerer, head of production and quality products, Siemens PLM Software.

Voegele agrees. "The Teamcenter and MRL connection was developed in response to numerous requests from shops wishing to streamline and secure the tool management process within a robust PLM system," he says. "Working with Siemens, we've accomplished that goal and further enhanced both of our products. This gives our VERICUT customers—both existing and future—another way to improve shop operations, reduce risk to expensive machine tools, and instill a sense of confidence in programmers and machinists alike."