Cool Flash System

Cool Flash System

Overheated cutting edges cause chip welding, tool chipping and ultimately decreased tool life. To compensate, operators frequently reduce spindle speeds or increase their consumption of cutting tools. Both options prove inefficient, as machining takes longer and the expense of constantly replacing dull tools can drain your bank account. The HAIMER Cool Flash system, based on the existing Cool Jet system for shrink-fit holders, was designed to guarantee an optimal coolant supply, even at the highest spindle speed, according to the company.

Overheated cutting edges cause chip welding, tool chipping and ultimately decreased tool life. To compensate, operators frequently reduce spindle speeds or increase their consumption of cutting tools. Both options prove inefficient, as machining takes longer and the expense of constantly replacing dull tools can drain your bank account. The HAIMER Cool Flash system, based on the existing Cool Jet system for shrink-fit holders, was designed to guarantee an optimal coolant supply, even at the highest spindle speed, according to the company.

To better understand the value of Cool Flash, it is important to note the limitations of existing coolant delivery systems where milling cutters are concerned. The two most popular coolant delivery methods are via external hoses or through coolant bores in the tool holder itself.

External nozzles at first glance appear to provide sufficient volume. However, they are often easily moved out of position and lack sufficient pressure to get coolant to the tool at higher rpm. Coolant bores in the holder, though more efficient at maintaining coolant position, also encounter problems with getting coolant where it is needed at high speeds.

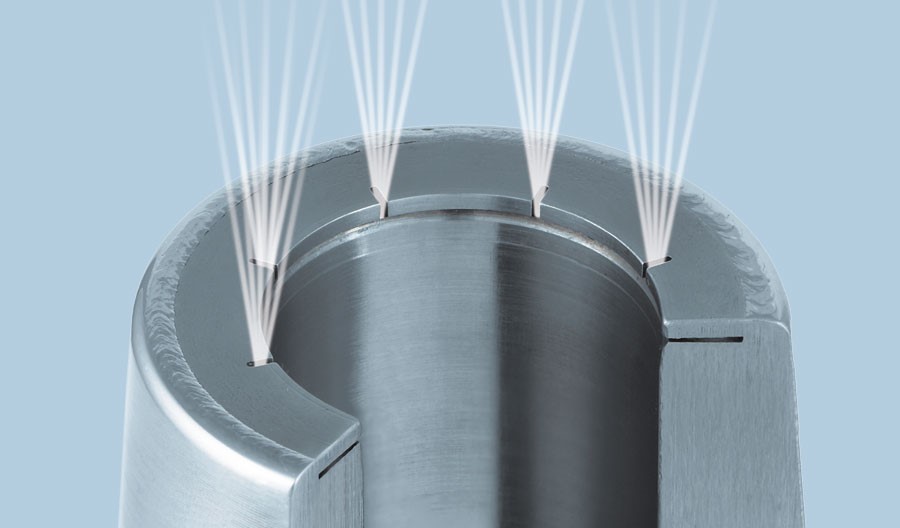

Tools rotating at high speeds create their own miniature vortex that form an air barrier around the spinning tip. Coolant aimed directly at the end of the tool runs right into this vortex, causing atomization that drastically reduces the volume of coolant actually reaching the cutting edge. The resulting heat buildup can cause chips to weld to the tool, thereby leading to tool breakage and workpiece damage.

To overcome this, we designed the Cool Flash system with a unique design in the nose of the toolholder to evenly deliver coolant directly to the flute and edge of the tool. This new design diverts the coolant into the T-slots and works with centrifugal force to lead the coolant along the shank of the cutter and directly to the flutes at any speed. This method not only minimizes the temperature of the cutting edge but also eliminates welded balls of chips on the cutting tool. The result is optimized runout accuracy and extended tool life up to 100 percent.

In addition to these benefits, the new HAIMER Cool Flash system is easy to use. No additional sleeves or separate holders are necessary, offering a decisive advantage over systems that entail greater effort while offering less optimal cooling. You can also shrink and unshrink HAIMER shrink-fit chucks as usual while using the Cool Flash option—no additional steps are required. Furthermore, stability, rigidity and interference contour of the original HAIMER holder remain unchanged.

The Cool Flash system is available in shank diameters from 6 mm to 20 mm.