CORINOX Machinist’s Files

CORINOX Machinist’s Files

Swiss pattern CORINOX machinist's files from PFERD are designed for use on stainless steel and exotic alloys. With a surface hardness of 1,200 HV and 70 HRC, these files offer enhanced wear resistance and long service life.

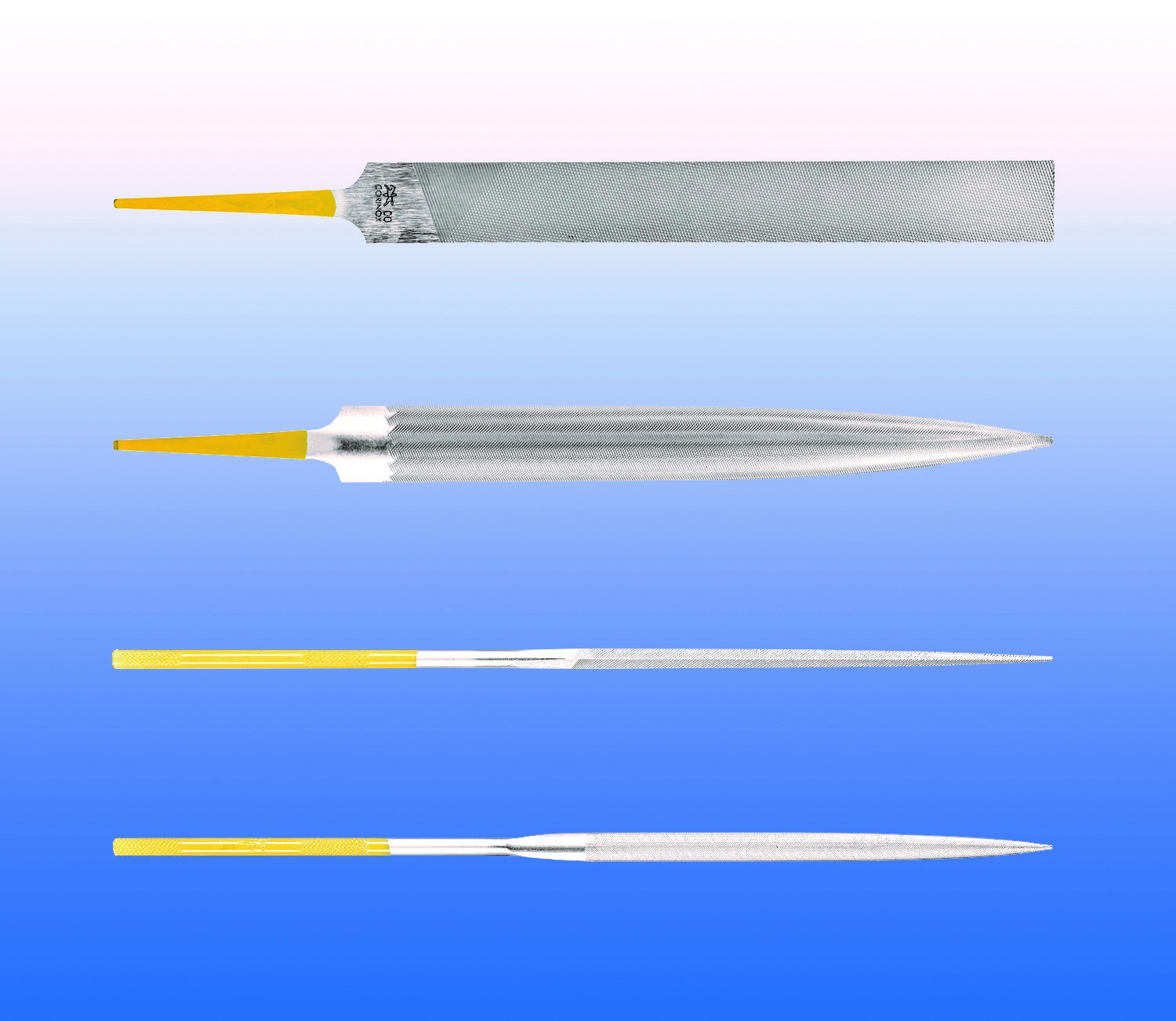

Swiss pattern CORINOX machinist's files from PFERD are designed for use on stainless steel and exotic alloys. With a surface hardness of 1,200 HV and 70 HRC, these files offer enhanced wear resistance and long service life. Their specially coated surface leaves no corrosive residue on the workpiece and effectively resists loading. They are available in a variety of configurations including pillar, half round, round, three-square, and needle.

The hand files are in lengths of 6 in. with a 5/8 x 5/32 in. cross section, 8 in. with a 25/32 x 7/32 in. cross section, and 10 in. with a 31/32 x ¼ in. cross section. Pillar files are in lengths of 6 in. with a 1/2 x 5/32 in. cross section, and 8 in. with a 9/16 x 7-32 in. cross section. The half round configuration is available in lengths of 6 in. with a 9/32 x 5/32 in. cross section, and 8 in. with a 3/4 x 7/32 in. cross section. The round configuration is available in an 8 in. length with a 5/16 in. diameter. The three-square comes in an 8 in. length with a 5/8 in. cross section. Square configuration files are available in a 6 in. length with a 7/32 in. cross section. Needle files are 7 in. in length.

CORINOX needle files are ideal for use in ultrafine, intricate stock removal on harder, temperature-resistant materials such as NiCo alloys and difficult-to-file materials like high-grade steels such as V2A and V4A, as well as high-temperature steels, rare alloys and fiber-reinforced plastics. Due to their high surface hardness, all CORINOX files are characterized by outstanding wear resistance and durability.

CORINOX needle files are suited for use in tool and die making, pattern making, turbine production and maintenance, aircraft production, and are available in various cross sections and cut densities.