Countersinks

Countersinks

A six-fluted countersink will remove more material per revolution than will a four-flute or single-flute tool. While the single-flute countersink is slow cutting, it will work well in a non-rigid machining setup. Four flutes provide more chip clearance than six do. This is a consideration in machining stringy materials such as some plastics and nonferrous alloys.

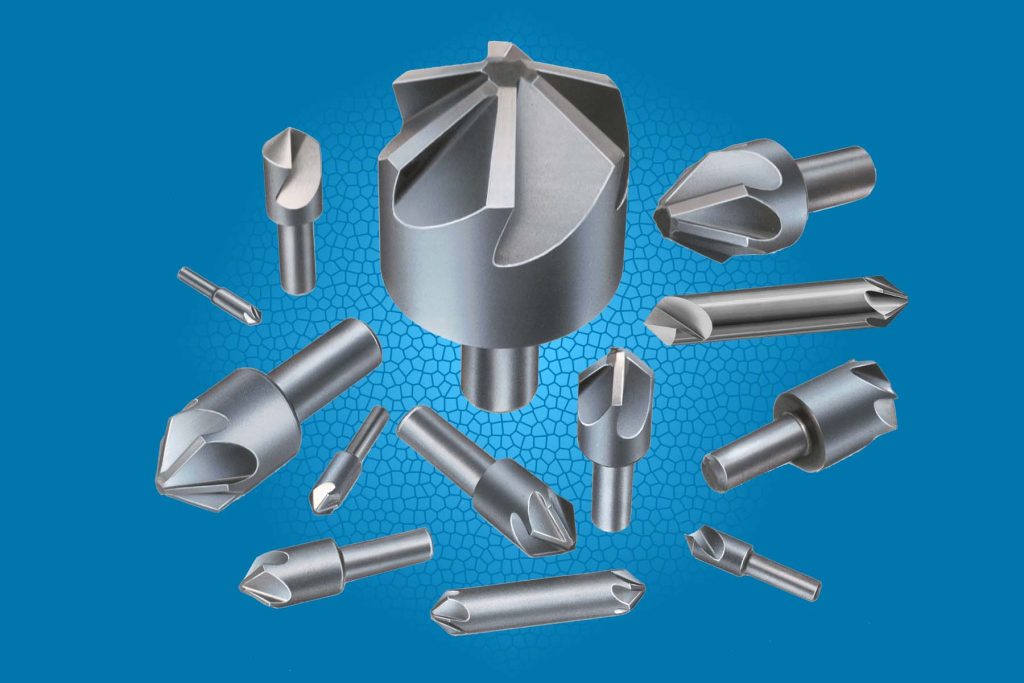

Severance Tool Industries, Inc. manufactures countersinks with one, four and six flutes, carbide and high speed steel, countersinks with pilots and drill points, heavy-duty tools and specials. Sizes range from 1/8" to 3", and almost any centerline angle can be specified. These standard tools will handle at least 99% of all countersinking applications ... and we can build specials to satisfy any other need.

Carbide or Steel?

When machining hard or abrasive materials, carbide countersinks will often give 10 or more times the service life of high speed steel tools. As a rule of thumb, consider carbide for production operations with cast iron, alloy steel or glass-reinforced plastics. High speed steel is generally more economical in low carbon steel and nonferrous machining applications. In automated production operations, the cost of changing a tool can exceed the cost of the tool. Consider long-running carbide in such situations.

1, 4, or 6 Flutes?

In general, a six-fluted countersink will remove more material per revolution than will a four-flute or single-flute tool. While the single-flute countersink is slow cutting, it will work well in a non-rigid machining setup. Four flutes provide more chip clearance than six do. This is a consideration in machining stringy materials such as some plastics and nonferrous alloys. Other factors being equal, the six-flute countersink will give more service life than the four-flute tool because the cutting load is distributed over more edges.

Chatterless Design

Resonant vibration is the cause of chatter in rotating cutting tools. Every tool/machine/workpiece system has natural frequencies at which such vibration will occur. Severance countersinks are designed with staggered cutting edges, which inhibit the occurrence of resonant, or harmonic vibration. Tools with symmetrical cutting edges tend to multiply the frequencies at which chatter occurs, and to reinforce the vibration. ChatterlessTM design can't change the natural frequencies of the system, but it takes tool geometry out of the problem.

Proprietary Countersinks for Special Jobs

What makes the Severance line unique is the number of proprietary and special tools we can supply to fit some specific applications.

• 3N1® Drill Points offer some cost-cutting opportunities to the creative tool engineer.

• CNC-KTM Precision Countersinks are used in numerical control and other preset tooling systems.

• Stop Countersink Systems are in wide use in the aircraft industry, where they are used with hand- held power tools to countersink rivet holes.

• Special Tools which combine countersinks with drills, steps, pilots, radii and other custom shapes are readily available from Severance. Just send in a sketch or description for quotation.