Customized CNC Tool Services

Customized CNC Tool Services

ShopBot continues to believe that everyone should be able to successfully employ the capabilities of CNC—making small- to medium-size shops competitive in today's market. That often can include configurations that make the tool better suited to the customer's production needs.

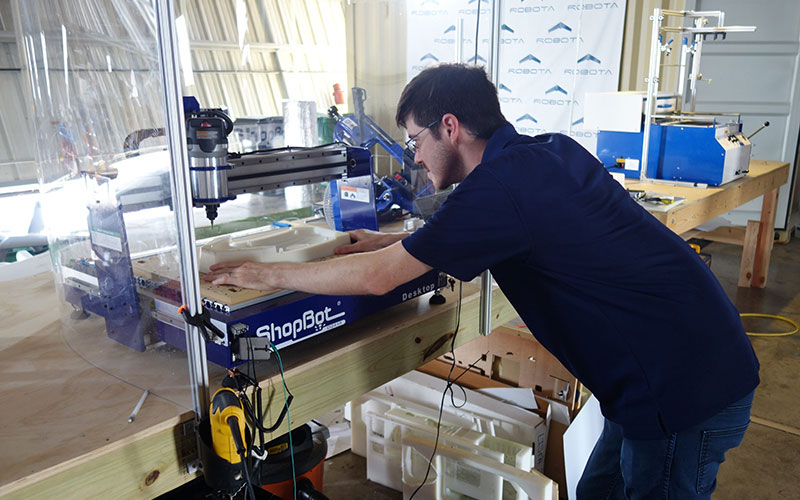

ShopBot Tools, an industry leader in the design and manufacturing of professional and affordable CNC routers, has announced the expansion of their Customized CNC Tool Services offerings. Making CNC technology and tools accessible to everyone has been a commitment from ShopBot Tools since first starting in 1996, and they've recently seen a new trend develop: An increase in requests for more customized CNC tools. Specializations include things like a deeper Z-axis, multiple spindles, tool sizes different than standard size offerings, and having a dedicated rotary axis, among others.

"Because ShopBot is the OEM for our machines and components; we take ownership of our projects from start to finish," says ShopBot COO Brian Owen. "We also handle all aspects for the customer from project scoping and design to procurement, assembly, shipment and installation. Since the people working on each step of this process are the same people that design and build our standard CNC machinery, they have the understanding and skills to work directly with the customer to learn about what they need from a CNC tool."

ShopBot continues to believe that everyone should be able to successfully employ the capabilities of CNC—making small- to medium-size shops competitive in today's market. That often can include configurations that make the tool better suited to the customer's production needs.

With 25 years of engineering and design experience, and the versatile, expandable, and upgradable nature of the ShopBot machine platform, ShopBot's engineering team will work with customers to spec out a tool to fit their custom application. "We work one-on-one with companies, big and small, as well as individuals, to get them the tool that they need," says ShopBot Lead Engineer, Ryan Patterson. "Because we have experience working with a wide range of materials, and are the people that design, build, and support the tools, we're able to help customers find a machine to fit their workflow and increase throughput in their shops."

ShopBot's array of CNC routers are used in prototyping, full production cutting, carving, machining, and milling in a variety of materials, including wood, MDF, plastics, foams, and soft metals. The full line of tools from ShopBot is oriented to be used for both standard and specialty operations. ShopBot's CNC tools are affordable yet deliver professional power and precision associated with heavier and more expensive CNC equipment.

Custom machines are available in any size. Businesses don't need to limit their production capabilities by trying to fit their unique application to the standard offerings of other manufacturers. ShopBot offers accessible expertise right here in the US paired with the excellent service for which they are known for in their industry.