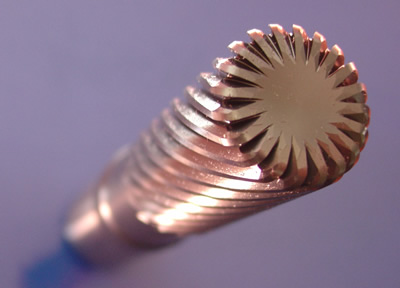

Cyclo Cut Max-Flute endmills

Cyclo Cut Max-Flute endmills

The Cyclo Cut Max-Flute high-performance endmills from MAG are for roughing titanium when machining at low torque. When the 16-flute endmills run at 2,037 rpm and 231 ipm, they can achieve metal-removal rates of up to 8"3/min. with 25 ft.-lbs. of torque and 9 hp.

The Cyclo Cut Max-Flute high-performance endmills from MAG are for roughing titanium when machining at low torque. When the 16-flute endmills run at 2,037 rpm and 231 ipm, they can achieve metal-removal rates of up to 8"3/min. with 25 ft.-lbs. of torque and 9 hp. When cutting titanium, 60 to 70 percent of the heat generated is normally transferred to the tool, dramatically reducing tool life. Max-Flute tools use shallow, radial WOCs, which transfers less heat to the cutting tool and allows higher surface speeds for roughing titanium, Inconel and other high-temperature alloys that have traditionally required high torque at low rpm to achieve desired removal rates, according to the company. When applied in conjunction with TrueMill software, Max-Flute endmills reportedly maintain a constant angle of engagement, making the radial cuts more consistent throughout the cutter path, increasing mrr and decreasing cycle times, while extending tool life. Max-Flute tools are designed with a differential pitch on the tool flutes to break up harmonics and reduce chatter.