DataPage+ 5.0 Statistical Process Control Software

DataPage+ 5.0 Statistical Process Control Software

Hexagon Metrology announced a new release of DataPage+ 5.0, statistical process control (SPC) software for quality assurance professionals.

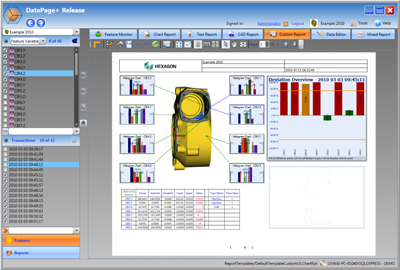

Hexagon Metrology announced a new release of DataPage+ 5.0, process control (SPC)">statistical process control (SPC) software for quality assurance professionals. The new version delivers meaningful, actionable and timely feedback to the shop floor to eliminate bottlenecks, reduce waste, and streamline manufacturing processes. DataPage+ 5.0 integrates seamlessly with PC-DMIS metrology software.

DataPage+ 5.0 offers a variety of new reporting features including an Assembly Qualified Rate Chart, which is similar to a Qualified Rate Chart, but allows the user to break out data by variable sets. The chart displays all variables within 75 percent of tolerance (green), between 75 percent and 100 percent of tolerance (yellow), and out of tolerance (red). Users will also find a new Measurement Deviation Chart showing deviation trends with color-coded tolerance indicators. A CII (Continuous Improvement Index) Variation Chart has been added to report deviation trends over a year-long time period, and on a monthly basis, will calculate Six Sigma of all dimensions with measured data.

"DataPage+ 5.0 is the most innovative commercial SPC software to date," said Ken Woodbine, President of Hexagon Metrology Software Division. "Our customers will garner measurable savings in time, resources and money due to the software's ultrafast database synchronization, enhanced graphics display engine, and seamless integration into our flagship software PC-DMIS. Our software development team packed an amazing amount of innovation and advanced technology into this simple-to-use and highly productive SPC software."

A new NG Details Report presents the rankings of each selected dimension, sorts the data based on the highest percent out of tolerance, and highlights the Top 10 based on lowest tolerance percent. A Customized Microsoft Excel Report tool allows the user to report variables and transactions in rows and columns, or columns and rows, allowing for easier template customization. This update also enables the use of all measured values as part of an Excel file.

DataPage+ 5.0 now includes a Windows Service option which keeps DataImporter running on the server as a "push" service. For example, when PC-DMIS places a part file in a specified directory, the DataImporter service automatically recognizes it and pushes the data to the database. The Windows Application option still exists for custom setups as part of legacy support. DataPage+ 5.0 also adds the ability to import data from PC-DMIS directly into a specific Part Category, allowing operators to view and import parts automatically, to streamline data input without interaction from the DataPage+ Administrator.