Contact Details

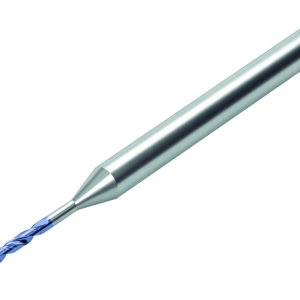

The versatile new DC160 Advance solid-carbide drill from Walter delivers high productivity in a wide variety of materials and can be used universally in an extremely broad range of applications. The newly designed drill offers many advantages. The margins are located in an advanced forward position to ensure rapid guidance in the hole. A steep gash angle provides ample space for secure chip flow resulting in improved hole quality and reduced feed force. Further, the drill provides superior positioning accuracy thanks to the innovative new thinner web, as well as improved roundness.

The new DC160 Advance solid-carbide drill, available in 3, 5 and 8xD, features grade WJ30ET, which includes a proprietary Walter coating for long tool life. It has a cylindrical shank ground to an h6 tolerance, which makes is suitable for shrink-fit and hydraulic holders. Point angle is 140° and recommended coolant pressure is 145-580 psi (10-40 bar). With internal coolant the versatile new drill is suited for a variety of ISO material types P, M, K, N, S, H and O.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- point angle

point angle

Included angle at the point of a twist drill or similar tool; for general-purpose tools, the point angle is typically 118°.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

PRODUCTS

PRODUCTS