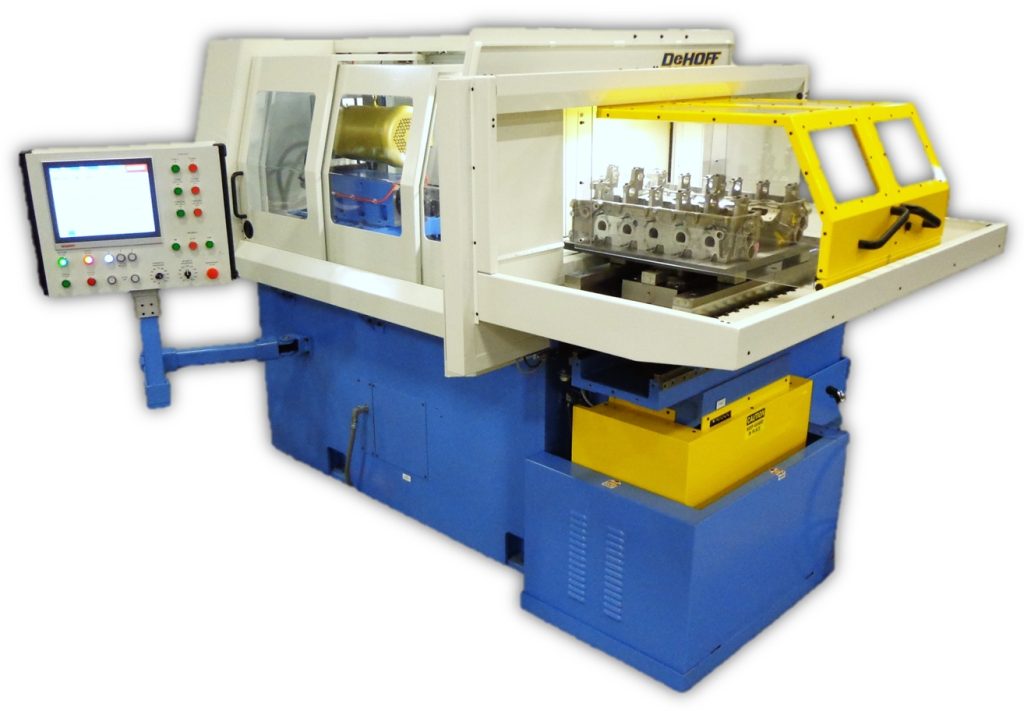

DeHoff 1036 CNC 3-Axis Boring Machine

DeHoff 1036 CNC 3-Axis Boring Machine

The DeHoff 1036 CNC is a 3-axis boring machine used for automotive engine rebuilds. The machine is custom designed for re-boring the cam journals of automotive engine blocks during a rebuild program.

The DeHoff 1036 CNC is a 3-axis boring machine used for automotive engine rebuilds. The machine is custom designed for re-boring the cam journals of automotive engine blocks during a rebuild program.

The 1036 CNC has a single spindle with a maximum boring capacity of 1 inch (25.4 mm) and maximum boring depth of 36 inches (914 mm). Multiple-axis capability is provided by a "knee" table, which allows for 21.5 inches (550 mm) of X-axis travel and 12 inches (300 mm) of Y-axis travel. The machine features Beckhoff controls with G-Code programming capability.

DeHoff machines feature steel box ways and hand-scraped mating components (instead of linear guide ways and milled surfaces). This results in enhanced vibration damping, extended tool life and improved surface finish.