DryLin W Linear Guide

DryLin W Linear Guide

DryLin W from igus Inc. was originally developed as a lubrication free, inexpensive alternative to linear guide systems that run on ball bearings.

DryLin W from igus Inc. was originally developed as a lubrication free, inexpensive alternative to linear guide systems that run on ball bearings. The flexible, modular design, available with various accessories, allowed for more design freedom than traditional linear guide systems. New fields of application for the linear guide systems, such as those on agricultural equipment, factory automation, and in the packaging industry, are calling on more from their systems, leaving room for igus to introduce the new size 25 to the DryLin W system.

DryLin W systems all rely on igus plastic linear plain bearing materials, the most common being J200. J200 was specifically formulated to achieve the best wear resistance and lowest friction against hard-anodized aluminum guide rails.

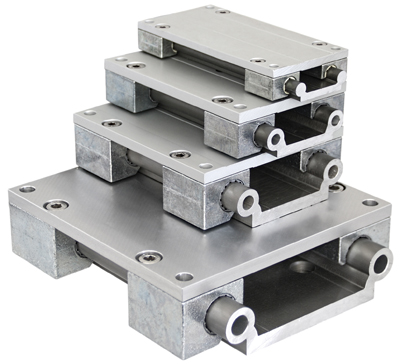

Like all members of the DryLin W family, the new size 25 model consists of three basic elements: a guide rail made of hard-anodized aluminum, the bearing housings made of a zinc die casting, and the plastic bearing liner, made of the tribo-optimized plastic iglide J200. The W25 guide rail is available in two configurations: the first is a single-sided 0.98" (25mm) bearing rail that spaces the two guide shafts 4.7" (129mm) apart.

The advantage of the double rail is that it eliminates the need for shaft alignment, easing assembly. The single rail offers the customer the ability to place them wherever the application demands. Rails are available from stock in lengths up to 13.2 ft.(4 m), and can be cut down to customer requirements, there is no cutting charge.

Compared to the other DryLin W sizes, these new dimensions allow for a higher load capacity, up to 1080 lbf, as well as resisting higher movements. Statically, each zinc die-cast bearing housings can withstand 1000 lbf.