e-CONNECT Solutions

e-CONNECT Solutions

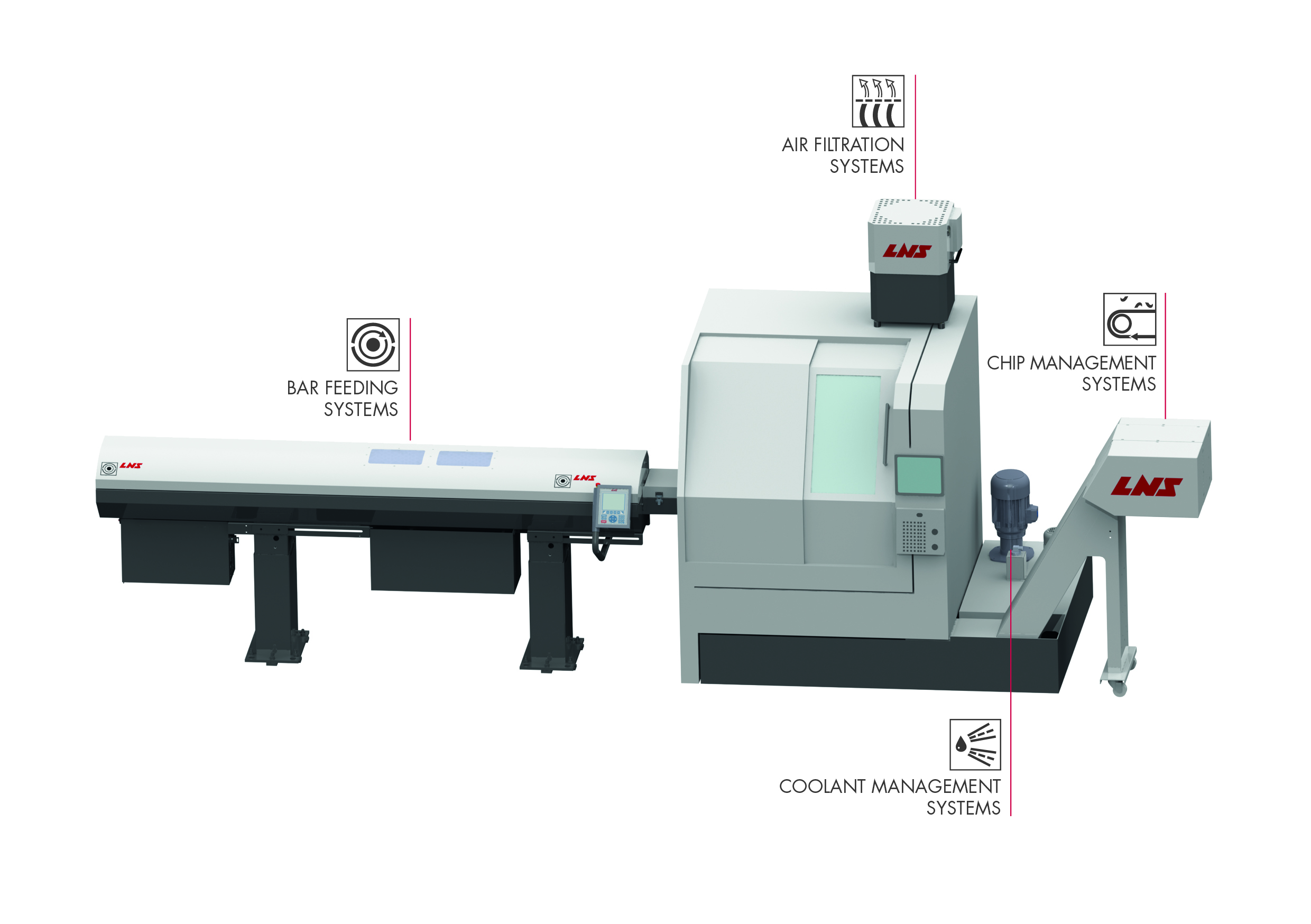

The LNS Group is implementing e-CONNECT solutions to integrate the company's products, in particular bar feeders, into its customers ERP (enterprise resource planning) and MES (manufacturing execution system) software.

The LNS Group is implementing e-CONNECT solutions to integrate the company's products, in particular bar feeders, into its customers ERP (enterprise resource planning) and MES (manufacturing execution system) software.

"This will allow LNS customers to get full transparency about their production at first glance. Workload of each machine, production cycle times and expected production completion – the user will get the full picture of the production in real time", explains Carlos Muniz, global product manager barfeed at the LNS Group. Large and small companies can benefit from putting their production equipment under control.

The LNS Group has been pushing innovation in the field of connectivity for more than 10 years. Together with major machine builders, the connection between the peripheral and the machine tool was developed. "This first step allowed LNS customers to drive the peripherals more process-oriented, to save time in installation, and to save resources in production. The production schedule could be automatically adapted to optimize the remaining material consumption, for example," said Muniz.

A second major innovation is the connection between the LNS product and the humans controlling it. Monitoring the production remotely from mobile devices saves time by knowing when the production will stop for changeover, and anticipating downtimes into the production planning. Thanks to e-mail or GSM notifications, overall production processes are more efficient. Additionally, the connection to internal or external technical support ensures downtime reduction. Muniz said: "Some of our clients have hundreds of barfeeders in their production. With state-of-the-art connectivity, the production manager can monitor all of them at once. For example, he can immediately see which barfeeders will run out of bars in the next 20 minutes."

While the e-CONNECT solutions to the machine tool and to the people are essential, another major step is the upcoming integration into the customers' ERP, MES and QC operations. "Until now, such systems and the machines are not efficiently connected, missing transparency. LNS is developing software drivers, which will gather relevant information from the peripheral, and, through a middleware, feed it to applications or systems such as ERP, MES or QC," explained Muniz. These solutions are tailor-made for each customer software platform. "The real-time monitoring of all processes will help clients to save time and resources. So to say, more efficient and thus, throughput improvement."