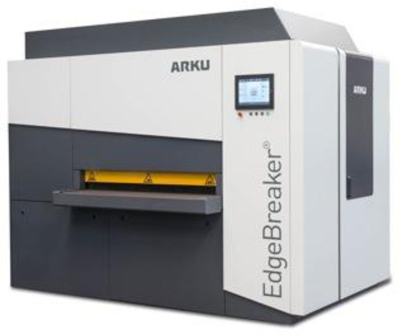

EdgeBreaker Deburring and Rounding Machine

EdgeBreaker Deburring and Rounding Machine

For decades, ARKU has made a name for itself in leveling technology and now the company is entering the deburring market with launch of the new EdgeBreaker deburring and rounding machine.

For decades, ARKU has made a name for itself in leveling technology and now the company is entering the deburring market with launch of the new EdgeBreaker deburring and rounding machine. "The time has come to expand our areas of competence and take the next logical step," said Albert Reiss, ARKU's managing director. "In order for our proven high-precision levelers to work even more efficiently, the use of deburring machines of equal quality and reliability is recommended. Therefore, we are building on our expertise in leveling, and applying it to burr-removal technology."

The EdgeBreaker represents the debut machine in the newly developed product line specifically adapted for parts with greater thickness. "From our many years of experience in leveling technology, we know that flatness results are improved when you start with a clean, burr-free part," explains Franck Hirschmann, ARKU's Key Account Sales Manager. "Our customers will now have the ability to obtain not only leveling machines, but also deburring machines, comprehensive consultation and service from a single source."

Whether this material is aluminum, steel or titanium, the oscillating roller equipped EdgeBreaker removes unwanted burrs, while transverse-running rounding units equipped with rounding locks, simultaneously round the edges on both sides. A patent-pending One-Click system allows for a quick replacement of the rounding blocks. Part parameter input is quick and easy using touch-screen controls. Once stored, the data can be retrieved at any time allowing the EdgeBreaker to run jobs automatically on just 25 kW. The Edgebreaker is a dry processing application and can perform double-sided deburring and rounding.

The EdgeBreaker is available for tests and contract deburring at the leveling and deburring center in Cincinnati. "With this broad performance spectrum, ARKU is providing support to sheet processors and helping them achieve time and cost savings," said Eric Cohen, ARKU's North American Sales Manager for deburring machines.