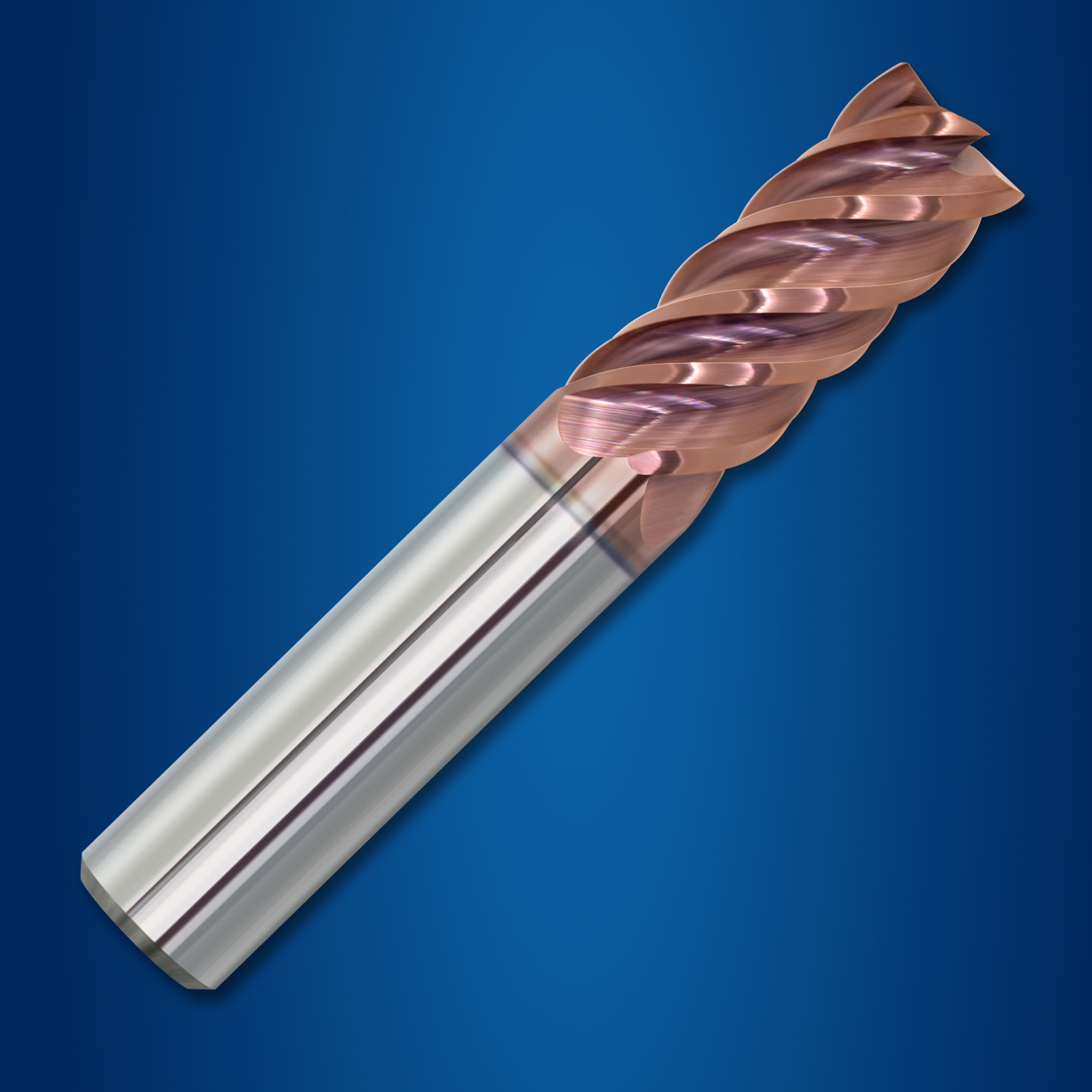

EIV5 Series Endmills

EIV5 Series Endmills

The EIV5 series from Millstar is revitalizing conventional practices for machine shops. With its combination of radial grind, variable helix, variable pitch and radius preparation, the EIV5 is a versatile endmill engineered for diverse machining applications.

The EIV5 series from Millstar is revitalizing conventional practices for machine shops. With its combination of radial grind, variable helix, variable pitch and radius preparation, the EIV5 is a versatile endmill engineered for diverse machining applications.

Reinforced cutting edge allows increased chip load without risk of edge failure.

Variable pitch accommodates large step-overs with no bottom vibration.

Variable helix eliminates side vibrations while achieving greater DOC.

Corner radius preparation allows longer machining times without radius failure.

Exceptional performance with high-temperature alloys like titanium at 300sfm 2xD with 20 percent step-over and a 0.6 percent chip load.