Electrically Interlocked Safety Shields

Electrically Interlocked Safety Shields

Rockford Systems offers a line of electrically interlocked safety shields for cutting and turning machines that protect operators against flying chips, sparks, debris, and coolant. The electrical interlock prevents machines from starting until the shield is positioned safely in front of the hazardous area, also called the point-of-operation.

Drill presses, lathes, grinders and milling machinery are essential metalworking tools, but like all machines, they can be dangerous without adequate safeguarding. Hundreds of injuries occur annually from the improper maintenance and use of these machines, such as amputations, burns and lacerations, according to the OSHA.

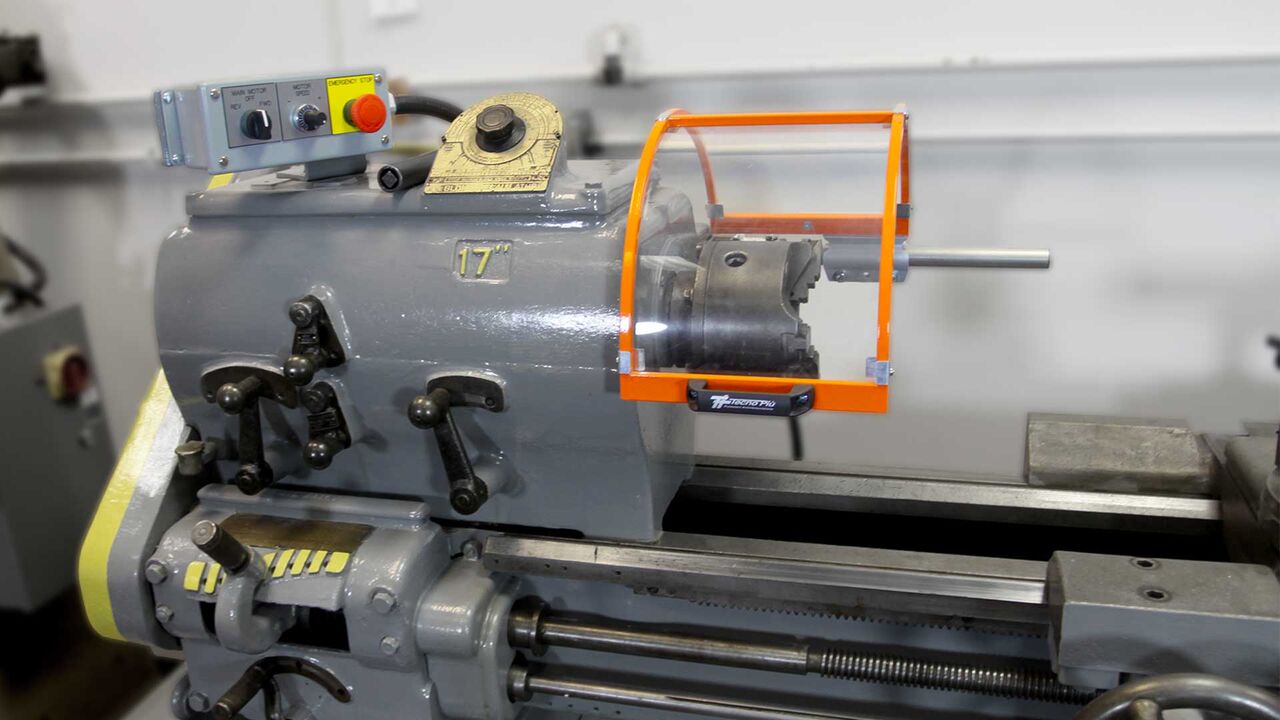

Rockford Systems offers a line of electrically interlocked safety shields for cutting and turning machines that protect operators against flying chips, sparks, debris, and coolant. The electrical interlock prevents machines from starting until the shield is positioned safely in front of the hazardous area, also called the point-of-operation. Additionally, if the shield is moved away from the hazardous area while the machine is running, the electrical interlock will send a stop signal to turn the machine off.

Fully embodying the Rockford Systems promise of durability and ease-of-operation, the thermo-formed shields are made from high impact-resistant, 100 percent transparent polycarbonate for minimum interference to the operator's view, and feature electrical interlocks encased in IP67 rated enclosures. The shields exceed the safety requirements of OSHA and the ANSI for maximum operator protection.

For metal fabricators, safety is the key to their livelihood - Rockford Systems interlocked shields ensure these professionals have the advanced safeguarding protection they need to maintain an injury-free workplace.

"It is not enough to simply meet the basic OSHA/ANSI requirements for chip shields as many manufactures do," says Matt Brenner, vice president of sales for Rockford Systems. "Our shields go further to deliver a game-changing combination of safety, versatility and operator visibility to ensure maximum performance, along with heavy-duty durability. Our standards are higher, which is why our shields are better."

Metalworking injuries often occur when an operator places their hands within the machinery's dangerous point-of-operation area. These injuries may happen during an accidental re-start while maintenance or setup tasks are being performed, or when the operator does not adhere to safety regulations and purposefully removes a shield for better access to a workpiece.

To prevent these types of accidents, Rockford System shields are electrically interlocked. This means that when a shield is swung out of position, the positive contacts on the safety microswitch open, sending a stop signal to the machine control. The machine's electrical circuit will stay disconnected until the shield is fully closed, the microswitch contacts are touching, and the start button is activated.

Rockford Systems shields are easily installed on small to large drill presses, milling machines, lathes, bench grinders, and slotting/broaching machines from leading manufacturers. Drill press and lathe chuck shields are supported by a rugged tubular-steel frame clamped to a 180° rotating steel support rod. Models designed for milling machines, crosslide/carriage travel lathes and grinders have an adjustable shield, arm and base to allow precise positioning for maximum protection during operation, yet can be swung out of the way for access to the workpiece and tooling.