ELM314x Economy Line

ELM314x Economy Line

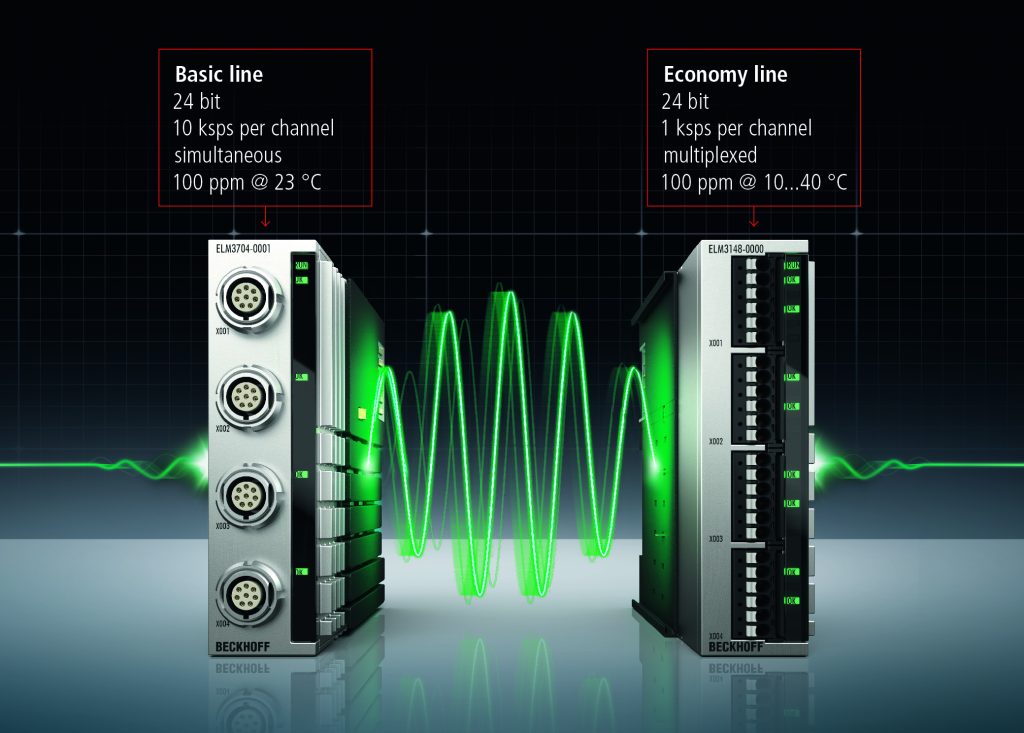

Beckhoff Automation has added the new ELM314x economy line to the EtherCAT measurement module family, supplementing the established ELM3x0x line with a lower cost 1 ksps class. This I/O system expansion simplifies the use of system-integrated precision measurement technology, which taps significant optimization and efficiency potentials both in production machines and for inline test benches.

Beckhoff Automation has added the new ELM314x economy line to the EtherCAT measurement module family, supplementing the established ELM3x0x line with a lower cost 1 ksps class. This I/O system expansion simplifies the use of system-integrated precision measurement technology, which taps significant optimization and efficiency potentials both in production machines and for inline test benches.

The new ELM314x measurement modules are available in two, four, six and eight-channel versions. High-precision measurements with an accuracy of 100 ppm are possible over a wide temperature range from 10° to 40° C. Each channel in the measurement modules can be set to current or voltage measurements with a sampling rate of up to 1 ksps per channel. Analog signals in the ranges from ±1.25 to ±10 V, 0 to 10 V, ±20 mA or 0/4 to 20 mA can be processed.

The new economy line offers considerably reduced channel costs, but provides the same wide range of functions as the ELM3x0x line. These include freely adjustable two-stage filters, oversampling, distributed clocks, true RMS and scaler functions. The extensive diagnostic features for unattended, long-term use familiar from the ELM3x0x line are also implemented.

Sampling at 1 ksps per channel is suitable for a wide range of applications. In particular, the processes of moving machine components or the final inspection stage of inline test benches can be optimally mapped with the economy line in order to reliably control the processes. Typical examples include part geometry measurement on the fly, as well as fast yet highly precise weighing procedures, such as in bottling plants. In general, the ELM314x EtherCAT measurement modules are ideal for recording data from 10 V/20 mA sensors and for feeding real-time information directly back into the process. The speed, reliability and accuracy of production and test processes can be increased significantly with these insights.

Efficient data logging for subsequent process analysis and optimization is also just as easy. If increased requirements necessitate higher sampling rates, the ELM3x0x measurement modules with up to 50 ksps can be used instead. These are suitable for vibration measurement on fast-running machines to implement active vibration compensation or predictive maintenance, for example.