eNET Machine Monitoring

eNET Machine Monitoring

Industry 4.0 is often referred to as "Smart Manufacturing," where technology enables interconnectivity for machines and manufacturing software and systems. It also provides big data, increased visibility and remote access to manufacturing assets. The rush towards Smart Manufacturing, which drives manufacturers to connect their systems to the IoT, has led to an inviting number of security gaps that are easy targets for hackers.

Industry 4.0 is often referred to as "Smart Manufacturing," where technology enables interconnectivity for machines and manufacturing software and systems. It also provides big data, increased visibility and remote access to manufacturing assets. The rush towards Smart Manufacturing, which drives manufacturers to connect their systems to the IoT, has led to an inviting number of security gaps that are easy targets for hackers. Manufacturing companies are trying to achieve the Smart Manufacturing goals of increased production efficiency, reduced waste/down-time, improved scheduling and inventory management from the IoT connectivity. Therefore, the manufacturing industry is the top buyer of IoT devices, and those connected devices on the shop floor are prime targets for cyber threats. According to a report released by NTT Security in 2017, manufacturing was the most cyber-attacked industry in the UK, accounting for 46 percent of all cyber-attacks.

What Do the Hackers Want from Manufacturers?

Hackers of industrial networks are interested in customer assets such as: data, intellectual property, banking information, and control of machines and robots, which can unfortunately cause damage and injuries in manufacturing plants. Cyber thieves routinely sell such proprietary data on the dark web, potentially to a manufacturer's direct-competitor or even foreign governments.

Legacy systems and machines that are no longer being updated often present prime targets for hackers, as networked legacy machines are not always compatible with the latest firewalls or antivirus software. Manufacturers are well-known for holding onto machines for as long as they can continue to make money off of them. Rarely does a manufacturer have all new machines that have a common secure communication protocol that is easy to manage.

The manufacturing workforce may be highly skilled labor, but often company training is lacking for IoT best practices. If there's a security hurdle that stands in the way of meeting production demands, often times manufacturing managers will disable that security, especially during times of high-demand, such as we face now.

It's not just manufacturers and their machines that are exposed by IoT connections. According to cybersecurity company Darktrace, in 2017 an unnamed North American Casino was the victim of a hack into which the cyber attackers gained access to the casino's network through an internet-connected fish tank thermometer.

What Can IoT Connected Manufacturers Do?

Manufacturers need to clearly understand that unless every IIoT device they have connected is always kept up-to-date with the latest security updates and patches, their networks will remain extremely vulnerable to cyber-attacks. Since there have been machines on the shop floor with Ethernet and Windows capabilities for more than 20 years now, fully securing these legacy assets can probably be best described as "mission impossible." With data security being such a major concern for connected devices, IoT manufacturers may even want to consider implementing one of the cyber-security insurance policies that are now available on the market. It highly recommended that organizations who leverage IoT technology have a plan in-place for when their networks get hacked. With so many vulnerable entrance points, it's no longer a question of if they'll be hacked, but rather when?

A Powerful and Secure Smart Manufacturing Alternative to the IoT

There is a simple yet effective alternative for achieving data-driven manufacturing goals. Rather than connecting machines and systems to the IoT, discreet manufacturers are increasingly deploying closed-loop machine monitoring systems that function solely within the well-protected environment of their internal Ethernet network.

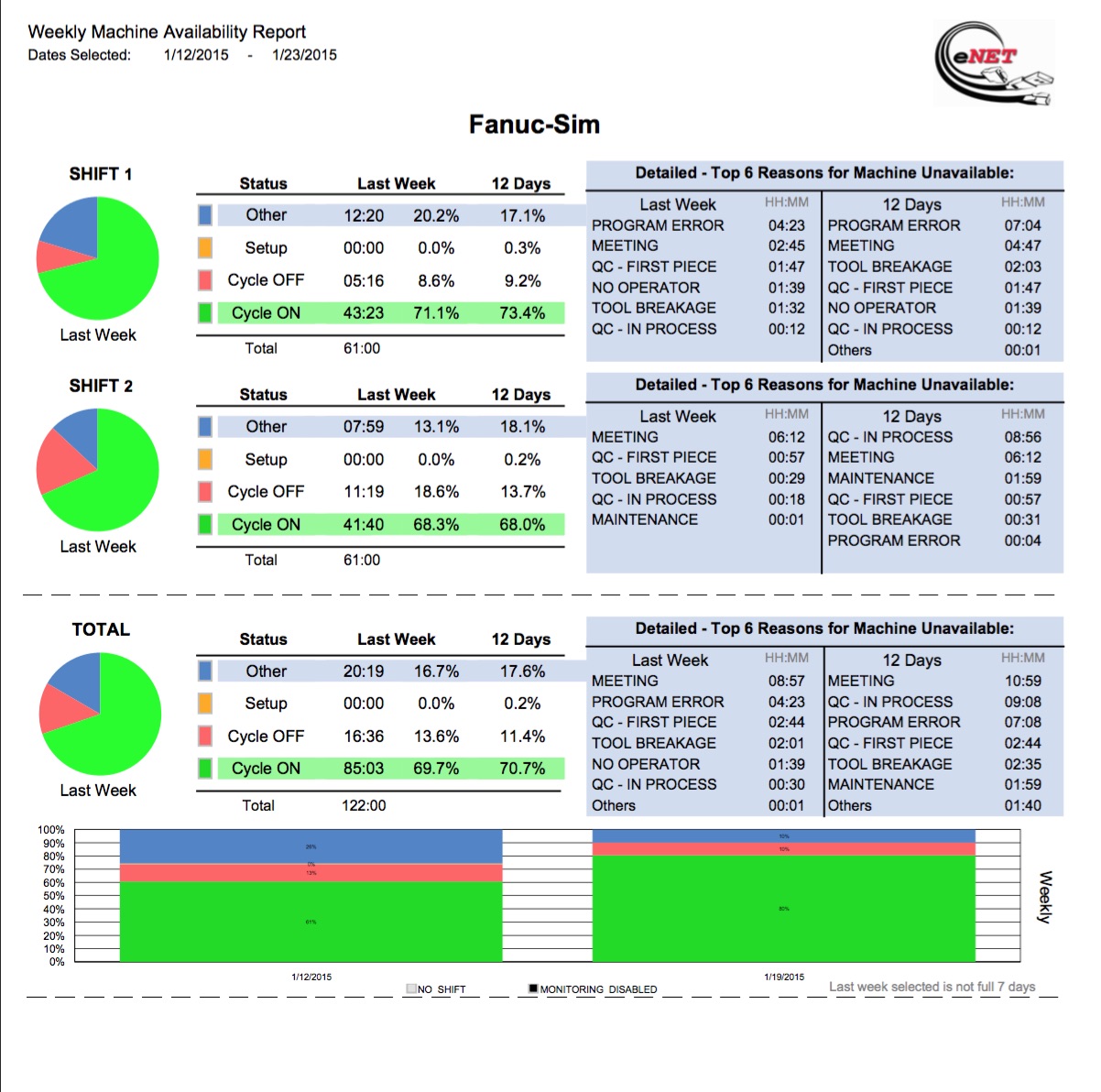

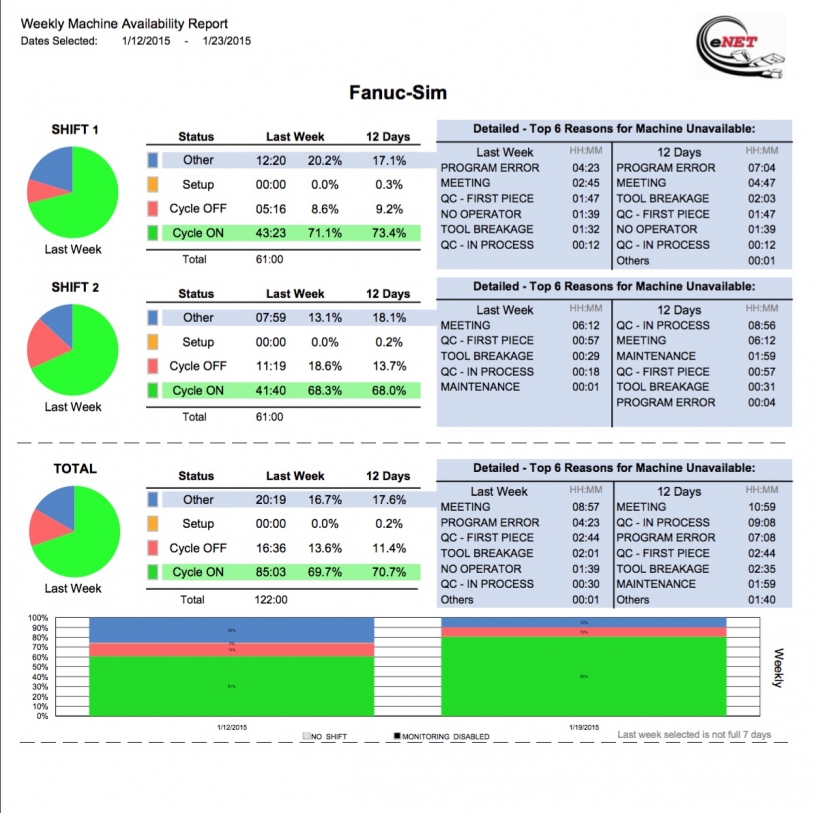

One such system is eNET Machine Monitoring, which installs data I/O boards into machines to automatically capture the exact production data that is most valuable to a manufacturer. It can even be utilized on manual machines. However, production data isn't the only information that can be gained through this type of system. eNET combines its monitoring boards with a software feature called "Cycle Start Disable." This allows for setting a predetermined time limit that a machine can sit idle before the operator is forced to enter a downtime reason code, which then unlocks the cycle-start button again.

So, unlike IoT systems that can only provide basic data for when the machine is running, eNET provides their customers with a true 24/7 in-depth understanding of their machine utilization. This unique approach to Industry 4.0 also allows for a single solution for your whole shop. Perhaps most importantly related to the genesis of this article, eNET Machine Monitoring has never been hacked or the cause of a customer's network becoming vulnerable to cyber-threats.