ERA 4000 Angle Encoder Series

ERA 4000 Angle Encoder Series

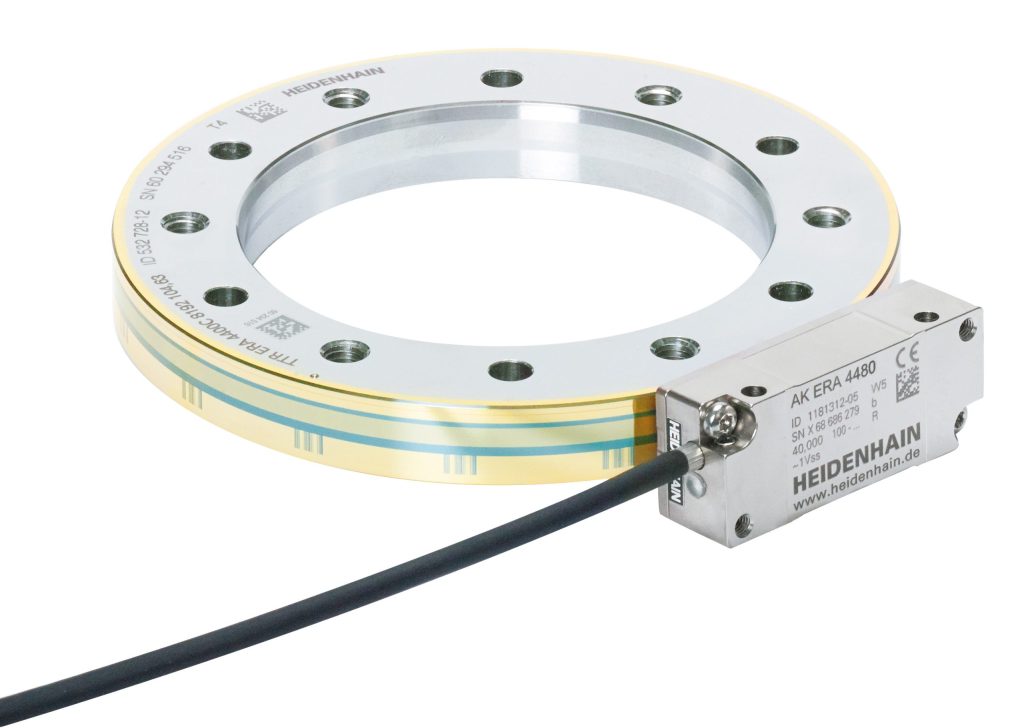

HEIDENHAIN's ERA 4000 angle encoders consist of a steel drum at various diameters with the 20-, 40- or 80-micron graduation on the outer diameter, and a scanning unit that reads the graduation. As an incremental system, there are reference marks available as distance-coded or one per revolution.

HEIDENHAIN announces several significant technical upgrades to the already successful ERA 4000 angle encoder series, thereby adding increased reliability and functionality upon a strong foundation. These bearingless encoders are used heavily in machines in the metrology, machine tool, semiconductor and robotic industries and have been for decades. With these upgrades, the new ERA 4000 series stands alone in accuracy, ease of use and logistical flexibility, and is exactly mechanically compatible with past models.

HEIDENHAIN's ERA 4000 angle encoders consist of a steel drum at various diameters with the 20-, 40- or 80-micron graduation on the outer diameter, and a scanning unit that reads the graduation. As an incremental system, there are reference marks available as distance-coded or one per revolution.

The most powerful upgrade to these encoders is adding HEIDENHAIN Signal Processing (HSP) to the scanning units. This feature is an added circuit where the LED is dynamically controlled, and where the scanning unit "learns" of the quality of signal coming back from the drum then adjusts the LED intensity on the very next signal period. HSP operates in an analog way and actually increases the speed capabilities of the encoder system to 1 MHz scanning, a 285% increase!

HSP also powers through contaminations on the drum like fingerprints, dust and liquid droplets, all without amplifying electrical noise as other encoders which are more sensitive to those types of contaminations often do. The result is improved reliability which results in less machine down time.

Two other upgrades to the scanning units are a status LED on the side of the scanning unit which provides unit status helpful during the mounting process, and the addition of a smaller M12 connector which saves space and is more robust.