ERD 150L Linear Automation System

ERD 150L Linear Automation System

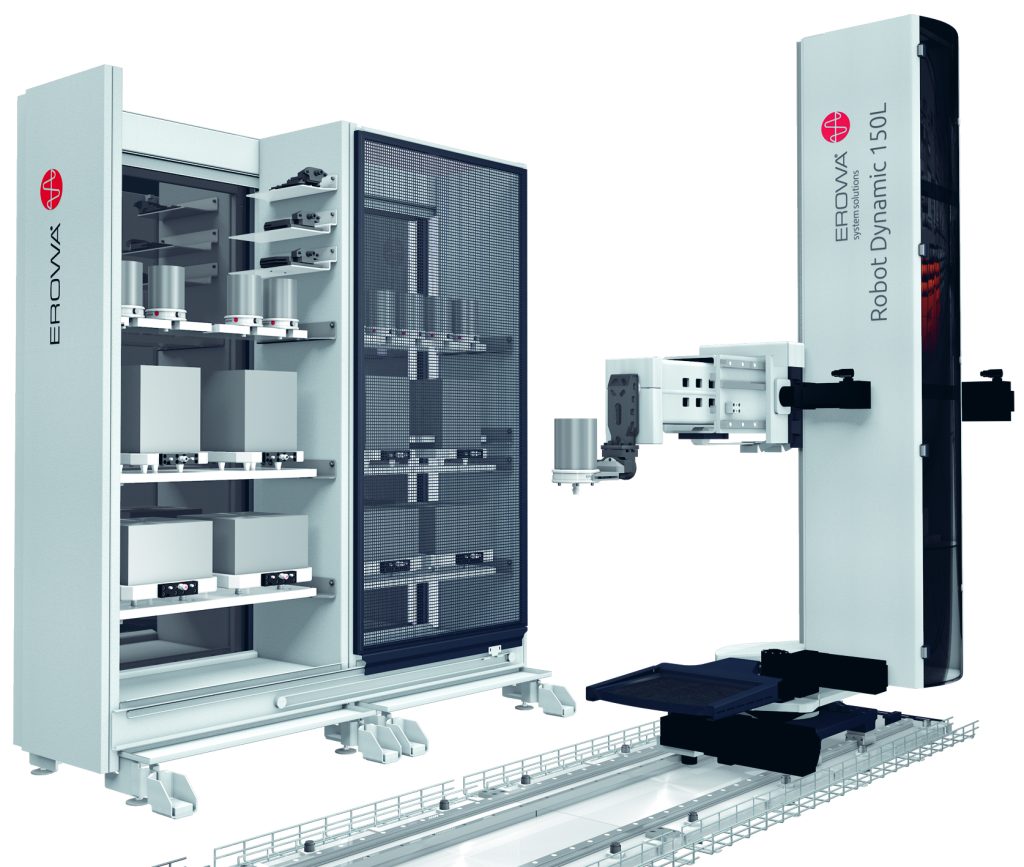

With the introduction of the ERD 150L, EROWA offers a low-cost, linear automation system that is flexible and can easily be expanded at any time. This virtually eliminates the need to purchase additional components before they're needed.

With the introduction of the ERD 150L, EROWA offers a low-cost, linear automation system that is flexible and can easily be expanded at any time. This virtually eliminates the need to purchase additional components before they're needed.

Due to lean construction, the space requirement is kept to a minimum. Even with this lean design, the telescoping transfer arm is capable of extending up to 54 inches (1,360 mm) and handles up to 330 lbs (150 kg). The central control unit is only equipped with connections that are required for the relevant cell. Additional connections can be integrated as components are added.

Being a modular system, the rail length of the ERD 150L can be expanded up to 100 feet. Additionally, the ERD 150L is able to service up to 12 machines while the selective magazine racks can be configured for a mix of pallets, electrode holders and fixtures.

Lastly, the ERD 150L incorporates virtual safety system which does not permit the transfer arm to extend past the working envelope. This safety feature allows for less expensive barriers which prevent operators from entering any dangerous zones.