ETEL XYZT Planar Platform

ETEL XYZT Planar Platform

ETEL announces the XYZT Planar Platform is now available in North America through HEIDENHAIN Corp.

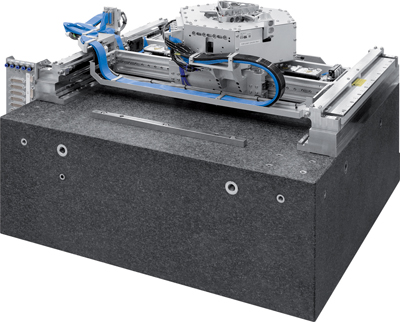

ETEL announces the XYZT Planar Platform is now available in North America through HEIDENHAIN Corp. The XYZT Planar Platform is a proven, reliable stage with over 100 units currently in the field worldwide. This system provides excellent dynamic flatness and bi-directional repeatability, making it suitable for a wide range of applications.

The XYZT Planar Platform is a hybrid mechanical/air bearing stage dedicated to step-and-scan applications. The stage is modular and can be outfitted with the components best suited to each individual application. Thanks to the flexibility of the platform, it has been used in wafer process control applications such as Critical Dimension and Thin Film Metrology, as well as in Wafer Scribing and Wafer Laser Thermal Annealing.

The hybrid nature of the XYZT Planar Platform allows the user to enjoy the best qualities of both mechanical and air bearings. The mechanical bearings provide high stiffness in the XY plane, allowing for high accelerations (up to 1.2g) and great bi-directional repeatability (+/-0.5µm for the X and Y axes). Thanks to the air bearing, the platform is also able to provide excellent dynamic flatness over the full range of travel.

The standard XYZT Planar Platform mounts an ETEL ZT Combined Module on the gantry beam of the XY stage. The ZT Combined Module provides infinite Theta rotation and dual Z-axes: a coarse Z axis for wafer loading and unloading, and a fine Z axis for focus adjustment. This module can be replaced to best suit the needs of an application, whether that application requires only Z motion, pure Theta motion, or ZT motion with tip/tilt correction. The stroke of the X and Y axes can be adjusted to accommodate a 300mm or 450mm wafer, and even longer strokes are also available. The platform can also be integrated with ETEL's QuiET Active Isolation System to further improve system performance.

The advantages offered by the ETEL XYZT Planar Platform include, but are not limited to, the following:

• Flatness of motion given by the air bearing

• Unlimited Built-in vacuum supply at chuck level

• Dual Z integration: Coarse travel for loading/unloading and fine travel for focus adjustment

• Compact footprint

• ISO2 clean room compatibility

• Position Stability of +/-25nm for X and Y axes, +/-15nm for Z axis, and +/-0.2arcsec for T axis

• Bi-directional repeatability of +/-0.5µm for X and Y axes, +/-0.3µm for Z axis, and +/-2arcsec for T axis