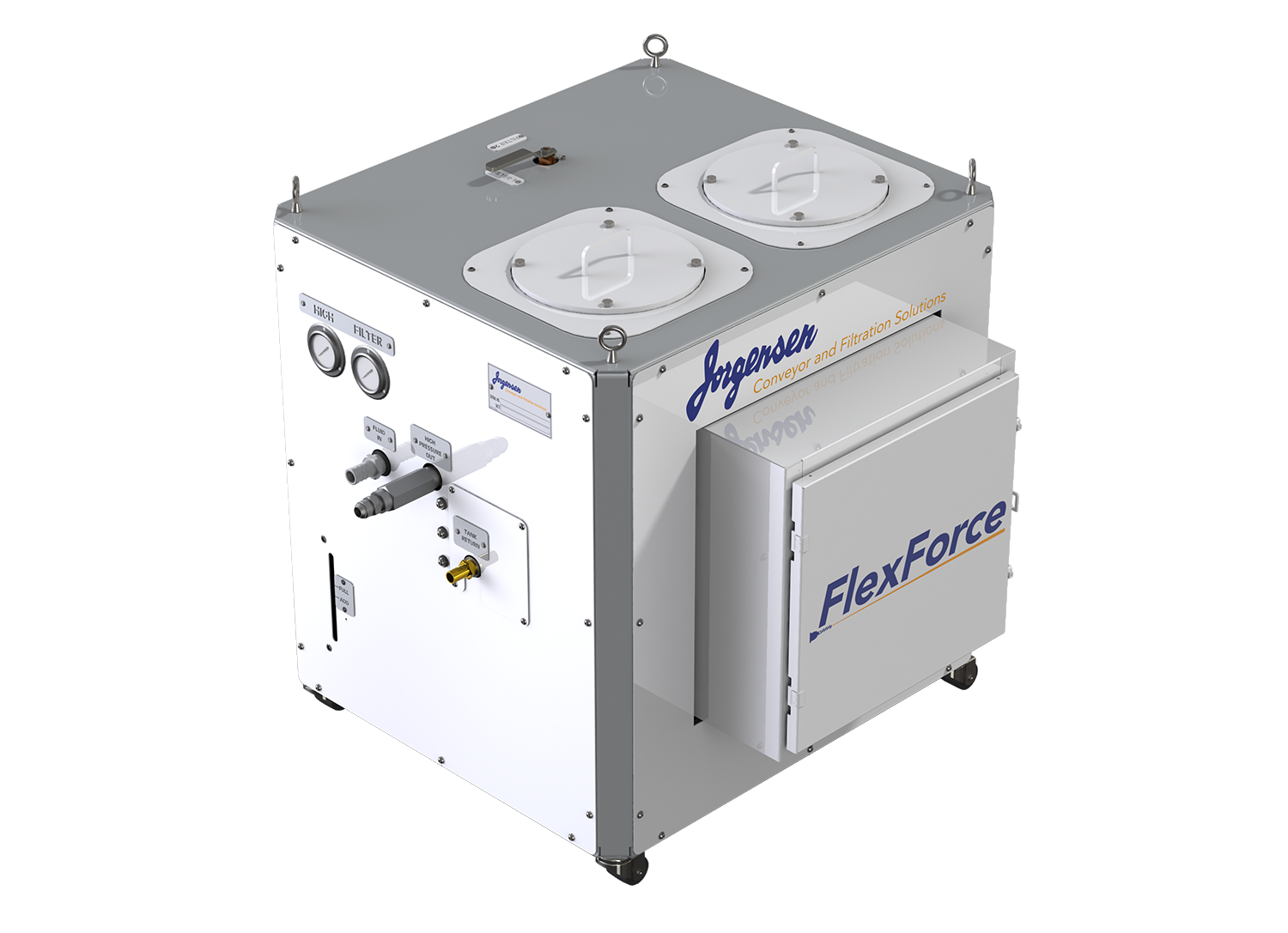

FlexForce Coolant System

FlexForce Coolant System

An onboard coolant reservoir continuously feeds FlexForce's high-pressure pump, and multiple electronic sensors monitor a variety of critical levels for lights-out operations. Automatic pressure regulators and machine-controlled dump valves, along with other fail-safes dramatically reduce or eliminate the risk of system damage.

Providing customers additional options and flexibility, Jorgensen Conveyor and Filtration Solutions now offers its advanced FlexForce high pressure coolant system with variable flow rates from two to eight gallons per minute (GPM). The variable flow rate options for the high-performance through-spindle coolant system (TSC) adapt easily to a variety of applications. The new flow rate options come in addition to Jorgensen's standard FlexForce unit with a flow rate of eight GPM.

Both the standard and variable flow rate options are available in 500 or 1,000 PSI configurations and are designed to break through the heat-generated vapor barrier created at the cutting tool and workpiece interface that causes surface deformities and damaged tooling. Because FlexForce gets coolant directly to the cutting zone, it improves lubrication and heat dissipation as well as cutting speeds and feeds, chip control and part surface finishes. Standard units filter to 10 microns; however, 5-to-25-micron filtration is available as an option, upon request.

Designed for fail-safe operation, a low-pressure suction pump draws coolant out of an existing coolant reservoir and through a bag filter into the FlexForce reservoir. From there a high-pressure pump sends pressurized coolant through the machine spindle and directly to the cutting point. As a result, faster machine feeds and speeds are possible for greater productivity.

An onboard coolant reservoir continuously feeds FlexForce's high-pressure pump, and multiple electronic sensors monitor a variety of critical levels for lights-out operations. Automatic pressure regulators and machine-controlled dump valves, along with other fail-safes dramatically reduce or eliminate the risk of system damage.

FlexForce provides safe and efficient operation in a maintenance-friendly design with a small footprint that easily integrates with existing coolant systems. FlexForce units can also be custom engineered for applications that fall outside the standard 500 or 1,000 PSI models.