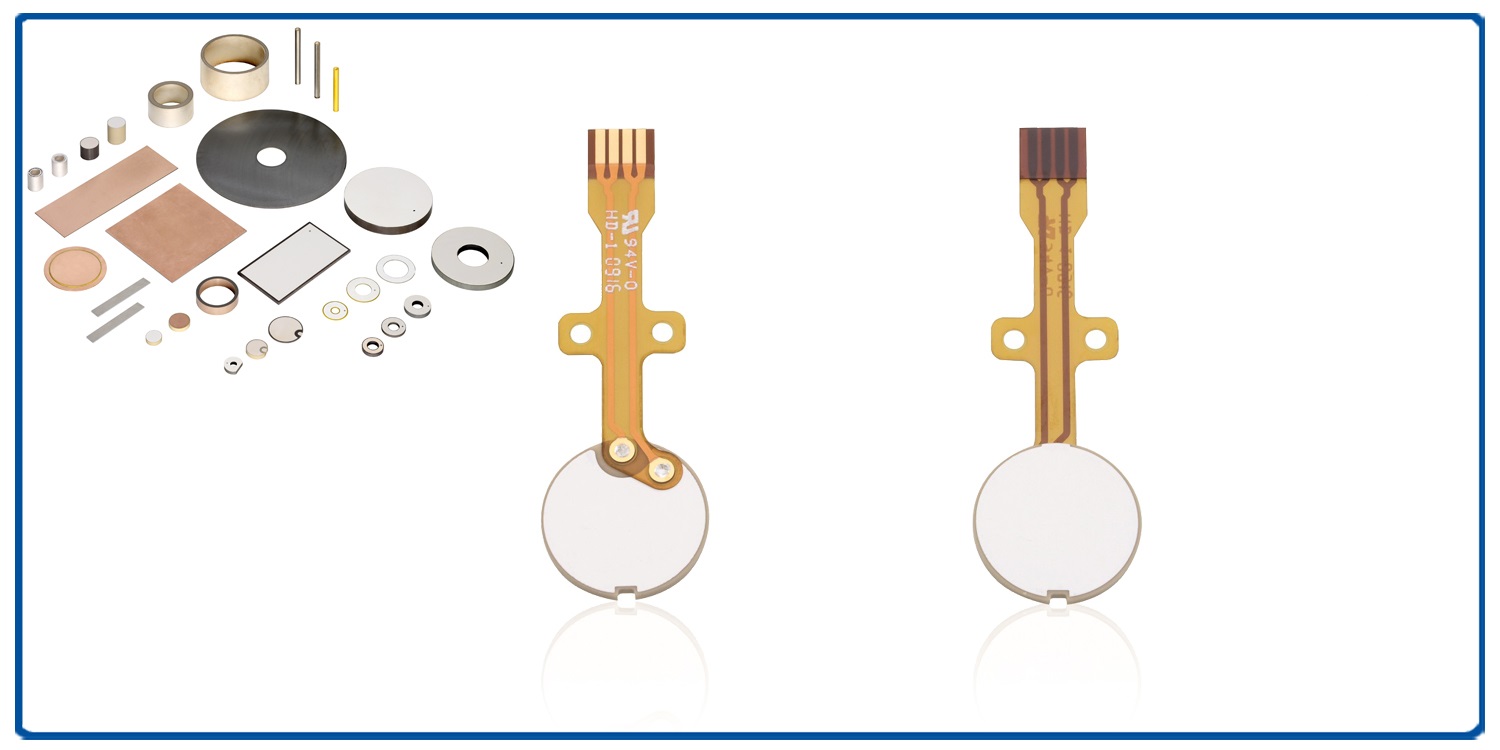

Flexible Printed Circuits

Flexible Printed Circuits

Fast response, high bandwidth and force, and virtually unlimited resolution make piezoelectric transducers invaluable to modern high tech applications including flow measurement, distance gauging, bio-medical dispensing and aerosol generation, as well as metrology, semiconductor testing, and aerospace technology. PI offers value-added piezo components by adhering flexible printed circuits for easy application integration.

Fast response, high bandwidth and force, and virtually unlimited resolution make piezoelectric transducers invaluable to modern high tech applications including flow measurement, distance gauging, bio-medical dispensing and aerosol generation, as well as metrology, semiconductor testing, and aerospace technology. PI offers value-added piezo components by adhering flexible printed circuits for easy application integration.

Piezo materials – mostly special ceramic formulations – generate an electric charge when a mechanical force is applied. This behavior is called the direct piezo effect. Conversely, when an electric field is applied to a piezo transducer, it will change its shape (inverse piezo effect). The response is fast, allowing oscillations in the ultrasound range up to millions of Hertz.

Traditional integration of piezo components requires soldering by experienced personnel to electrically connect the transducers. PI's new flexible printed circuits provide the necessary electrical contact, securely and easily, without soldering. Automated attachment is possible, reportedly providing greater versatility and saving cost and time-to-market.