FORTiS Enclosed Linear Absolute Encoders

FORTiS Enclosed Linear Absolute Encoders

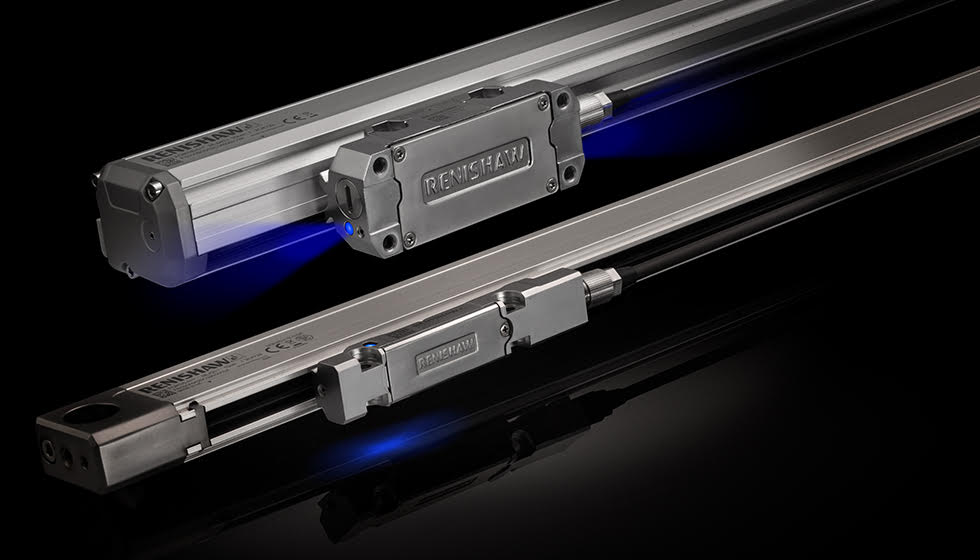

The FORTiS design is built upon industry-proven RESOLUTE™ encoder technology and provides high resistance to the ingress of liquids and solid debris contaminants. It features an extruded enclosure with longitudinally attached interlocking lip seals and sealed end caps. The readhead body is joined to a sealed optical unit by a blade, which travels through the lip seals along the length of the encoder.

Renishaw, the global metrology specialist, launches the innovative FORTiS enclosed linear absolute encoder series, for use in harsh environments such as machine tools.

The FORTiS design is built upon industry-proven RESOLUTE™ encoder technology and provides high resistance to the ingress of liquids and solid debris contaminants. It features an extruded enclosure with longitudinally attached interlocking lip seals and sealed end caps. The readhead body is joined to a sealed optical unit by a blade, which travels through the lip seals along the length of the encoder. Linear axis movement causes the readhead and optics to traverse the encoder's absolute scale (which is fixed to the inside of the enclosure), without mechanical contact.

Customers can choose from two different extrusion profiles to suit their space requirements. The FORTiS-S™ linear encoder is the standard-sized encoder, available with measuring lengths from 140 mm to 3040 mm and is installed directly to a machined surface via flexure holes in the extrusion's body. The FORTiS-N™ encoder, available with measuring lengths from 70 mm to 2040 mm, features a narrower cross-section extrusion and a more compact readhead to enable installations in confined spaces. This model can be mounted directly to a machined surface via two end cap mounting holes or a mounting spar for greater rigidity.

Ian Eldred, FORTiS Principal Mechanical Engineer at Renishaw, highlights a range of unique and ground-breaking design features:

"The new FORTiS enclosed absolute encoder range is the culmination of years of R&D effort at Renishaw. It delivers superior repeatability, reduced hysteresis and improved measurement performance due to an innovative non-contact mechanical design that doesn't require a mechanical guidance carriage. Five years of accelerated life testing, under the harshest conditions, has enabled Renishaw to develop and refine the new advanced DuraSeal™ lip seals. These offer excellent resistance to wear and machine tool lubricants, superior sealing and ingress protection up to IP64 when combined with air purge."

He continues, "FORTiS absolute encoders also feature integrated, specially-designed tuned mass dampers that deliver class-leading 30 g vibration resistance and push the limits of what enclosed encoders can endure. Installation of FORTiS encoders is quick and easy, which will help our customers save manufacturing and servicing time."

Benefits of FORTiS absolute encoders

The FORTiS absolute encoder series is designed to be robust and resistant to a wide range of mechanical shock and vibration effects. All FORTiS-S encoders, and FORTiS-N encoders when installed with mounting spars, are rated up to 30 g which ensures dependable metrology for even the harshest environments and demanding motion control applications.

In addition to its extruded enclosure, FORTiS encoders are also protected against contamination by a further level of sealing: the readhead optical unit (which runs inside the enclosure) is itself sealed to IP67 to prevent contamination by liquids, swarf and other debris. Moreover, improved sealing of the FORTiS encoder enclosure reduces air leakage from the air purge system, resulting in lower operating costs and greater system longevity.

FORTiS encoders feature a range of serial communications protocols including BiSS C, BiSS Safety, Siemens DRIVE-CLiQ, FANUC, Mitsubishi and Panasonic. The encoder dimensions also ensure space and bolt-hole compatibility with a wide range of alternative current and legacy systems.

Unlike traditional installation methods, peripheral diagnostic equipment is not essential. Renishaw's patented set-up LED and carefully designed installation accessories ensure intuitive and right-first-time installation that is substantially faster than more conventional systems, even in restricted locations.

For enhanced functionality, installers can connect the Advanced Diagnostic Tool, ADTa-100, via a standard USB connector, to a PC running Renishaw's ADT View software. This provides a user-friendly graphical interface of advanced diagnostic information, including key encoder performance parameters such as signal strength along the axis length. A permanent record of installation data can be saved providing confidence to both machine builders and users.

Renishaw FORTiS absolute encoder systems have CE approval and are manufactured in-house using strict quality-controlled processes that are certified to ISO 9001:2015 and backed by a global sales and support network.