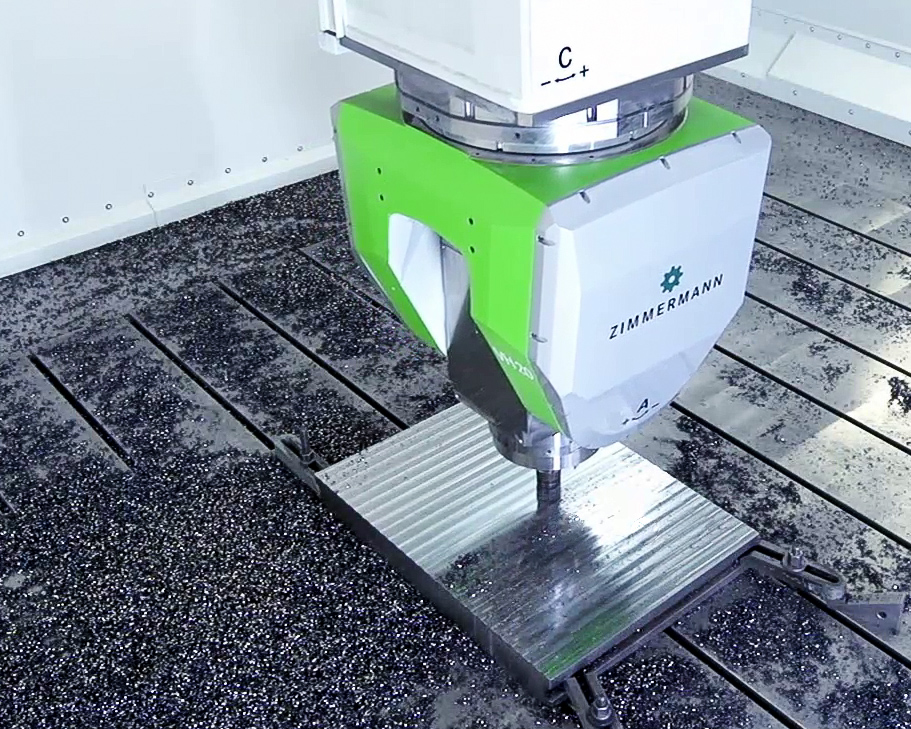

FZ33 Compact Portal Milling Machine

FZ33 Compact Portal Milling Machine

F. Zimmermann GmbH has extended the working area of its proven FZ33 compact portal milling machine. The Y-axis now travels up to 4,000 mm and the Z-axis up to 1,500 mm.

F. Zimmermann GmbH has extended the working area of its proven FZ33 compact portal milling machine. The Y-axis now travels up to 4,000 mm and the Z-axis up to 1,500 mm. This machine is used for the economical machining of small and medium-sized components for the aeronautical and automobile industries, tool and mould making, as well as for many special applications. This new version therefore enables users to process an even wider spectrum of workpieces.

The FZ33 compact has become established with users in various sectors since its launch in 2013. The special feature of the range is its inherently rigid cast iron base with integrated table. Mounted on this are side walls filled with special concrete, and a structurally rigid portal. This enables businesses to erect the machine on a solid industrial floor, usually without special machine foundations. Its particularly high performance and stability enable aluminum components and components made from composite materials, for example, to be quickly and economically machined on five axes. Users can also mill steel and cast iron components with excellent dynamic performance. In doing so, the FZ33 compact achieves short throughput times, high availability and high precision. Workpieces, therefore, no longer have to be reworked after removing from the machine. These characteristics, coupled with the increased working area, enable users to adjust even more flexibly and quickly to different component sizes, materials and complexity.

F. Zimmermann's range features various innovative and patented milling head technologies for this portal milling machine. These include the VH30 milling head, which Zimmermann offers as an option with a more powerful spindle. The power was previously 60 kW and the torque 95 Nm. The user now also has 70 kW and a torque of 167 Nm at his disposal. The machine builder also provides a tool holder in the form of the HSK-A100. As a result, the new FZ33 compact is even more reliable when used for hard materials with difficult machining characteristics.

F. Zimmermann has also made design improvements to the new FZ33 compact. The machine is significantly easier and quicker to assemble thanks to modifications to the electrical and media cabinet. In spite of the larger working area, the Zimmermann designers have reduced the footprint by 120 mm. These two improvements provide more flexibility for businesses when it comes to installing the machine. F. Zimmermann has placed great importance on user-friendliness. The operating platform can be pushed apart, thus providing better access to the portal milling machine and enabling operators to load the machine more easily, for example using a stacker truck.

Depending on the material processed by the user, the new design gives him the option of dry and wet extraction and a combination of both. He also has a choice of various belt filter systems and different tool changers: Zimmermann provides 50 and 60-pocket chain-type changers as well as a hinged changer version.

New features include the cast-iron cross slide and stiffer drive trains in the X-consoles. These make the FZ33compact even more stable in operation. The sheet steel housing has also been improved. This impresses not least with an enhanced appearance and optimised sealing. Thanks to the standardisation of assemblies, the modular construction of the machine and the stocking of assembly parts, F. Zimmermann can offer the FZ33 compact at an attractive price. Owing to its high value for the user, the costs are amortised within a very short time.