FZU22

FZU22

The FZU22 boasts a substantial working range, from 71"-98" in the X-axis, 118"-138" in the Y-axis and 49" in the Z-axis. A feed rate of 2756 ipm in the X- and Y-axes is standard while the acceleration on the machine is max. 118-197 in/sec2. With a compact footprint of 11' x 15', the machine fits in the corner of any shop. ISO 230-2 accuracy is provided. A choice of milling heads is offered on the machine to suit a variety of applications.

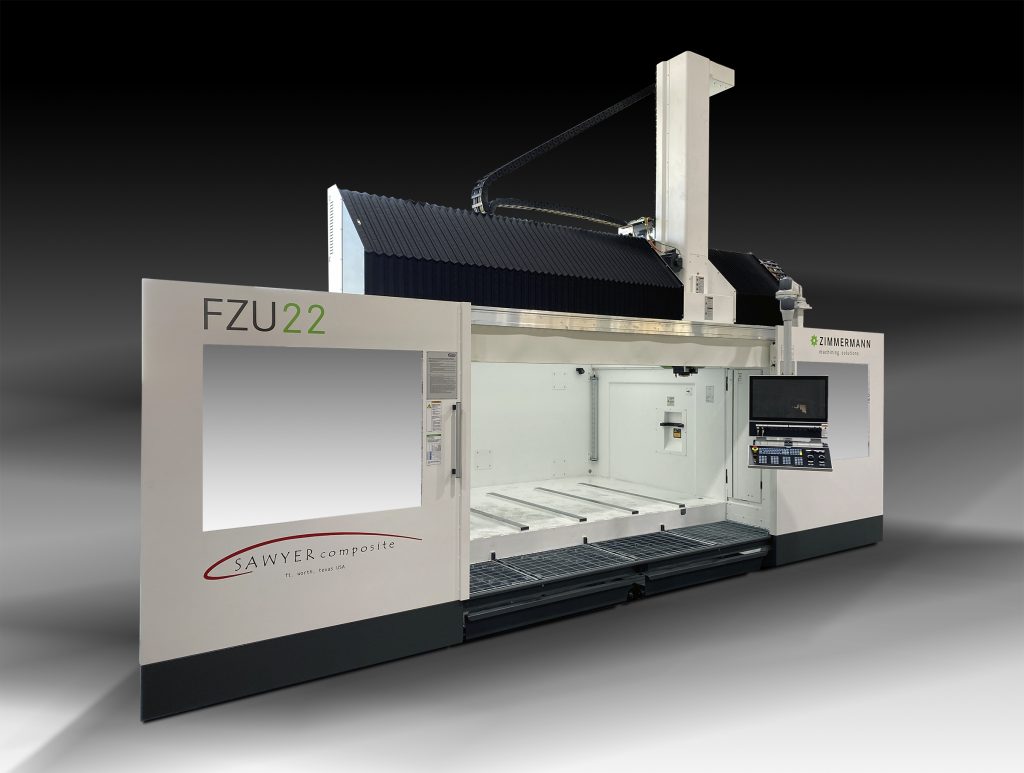

With the introduction of FZU22, Zimmermann has added a 5-axis portal milling machine for the machining of various workpiece shapes, sizes and materials. Aluminum, plastic, wood and other substrates can be processed, plus the machine is ideal for the finishing of carbon fiber reinforced and other composite materials. The overhead gantry provides precise production of models and molded parts. The standard machine includes a toolchanger for 24 tools and a CNC from Siemens or Heidenhain for full motion control and tracking. A specially developed 5-axis milling head with 15kW spindle is suitable for machining contours and tight pockets in large molds.

As Zimmermann Inc. President Cornelius Kiesel observes, "With this new machine, being introduced in our booth at IMTS to the North American market, Zimmermann enters a new arena, that is, the lighter weight machining applications for large structures at an economical price. Our recent acquisition of a company in Germany allows us to partner with a reliable source for this type of machine, enhanced by the unique features which have made Zimmermann a standard in the aerospace and large mold market segments."

The FZU22 boasts a substantial working range, from 71"-98" in the X-axis, 118"-138" in the Y-axis and 49" in the Z-axis. A feed rate of 2756 ipm in the X- and Y-axes is standard while the acceleration on the machine is max. 118-197 in/sec2. With a compact footprint of 11' x 15', the machine fits in the corner of any shop. ISO 230-2 accuracy is provided. A choice of milling heads is offered on the machine to suit a variety of applications.

Optional equipment is offered on the FZU22, including touch probe, tool measuring system, work area cover, tool changer, chip conveyor, mist/dust extraction system, minimum quantity lubrication and a vacuum system.

The machine to be displayed at IMTS also features an ultrasonic system for cutting aerospace insulation.