Contact Details

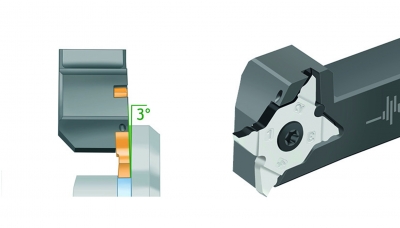

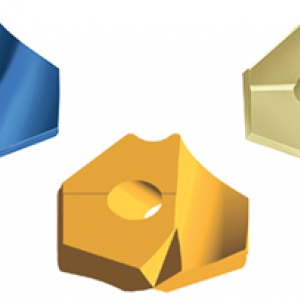

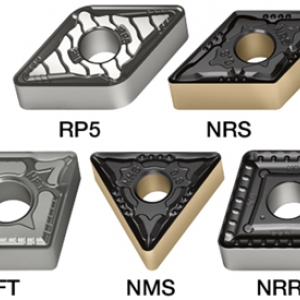

Walter has introduced a new system specially designed for grooving along a shoulder with the G3051-P groove turning holder and the new MX22-2L/R indexable inserts. The new system features an insert installation position inclined by 3° in the insert pocket. Both right- and left- hand versions of the inserts are available. This new feature enables deep grooving operations possible along the shoulder. The precision-ground, four-edged indexable MX inserts are available with new GD8 and VG8 geometries.

The GD8 geometry has been specifically developed for grooving along the shoulders and grooving of large diameters without interference of the insert with the finished workpiece. The VG8 geometry has been developed for finishing operations behind a collar. Thanks to its reduced space requirements due to unique narrow shape, savings on workpiece material are possible in mass production compared to conventional V-style ISO turning inserts.

The G3051-P grooving system can be used on CNC lathes and multi-spindle machines, as well as automatic lathes. These new holders are designed with Walter precision cooling as a standard feature and are available in shank sizes of 0.625-1.0 in. and 12-25 mm. They allow for cutting depths of up to 0.197 in. (5 mm) and insert widths from 0.059-0.118 in. (1.5-3 mm). This selection makes it particularly suited to high volume production of smaller components, such as camshafts in the automotive industry, but also for precision parts in the medical device industry.

Additionally, with the standard large contact surfaces and the patented dowel pin location in MX indexable inserts, leads to a high degree of stability, precision and indexing accuracy. The tangential arrangement of the grooving inserts results in outstanding flatness and surface quality.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS