Contact Details

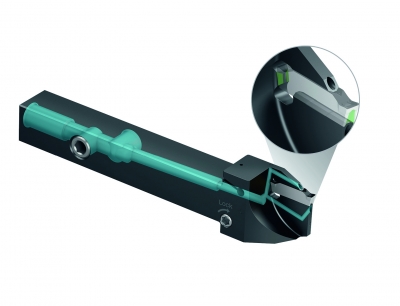

The new Walter G4014-P grooving tool holder is ideal for small part machining operations such as swiss type machining. The system offers an innovative new “SmartLock” insert clamping feature to access the clamping screw from the side.

This makes it possible to change inserts in the machine – even where space is limited—in particular on long center lathes and multi-spindle machines. As a result, changing inserts is approximately 70% faster. The clamping forces are around 30% higher than those of existing tools in the market, increasing the stability and enabling users to achieve a significantly longer tool life. The clamping screw can be accessed from either left or right side; thus, the operation of the tool from either side is possible, making it a very flexible system.

The patent-pending positive engagement design of the insert seat also contributes to the flexibility. The cutting insert is seated in the insert pocket with an innovative prismatic design. This prevents incorrect engagement, especially for narrow insert widths, and enables an extremely high level of indexing accuracy. The Walter grooving system consisting of G4014-P and DX18 inserts is available in the shank sizes of ½- 5/8 in. and 10–20 mm, with insert widths from 0.059-0.118 in. (1.5–3 mm) and for parting off diameters of up to 1.38 in. (35 mm).

The holder designs are offered with either precision cooling on the rake and flank faces or without internal cooling. These special features make the system the current benchmark in terms of the mass production of small parts like shafts, plug contacts, nozzles or implants. Typical applications include automotive suppliers, medical engineering as well as the electronics, food processing, watchmaking and general engineering industries.

Related Glossary Terms

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS