GBF Grooving Series

GBF Grooving Series

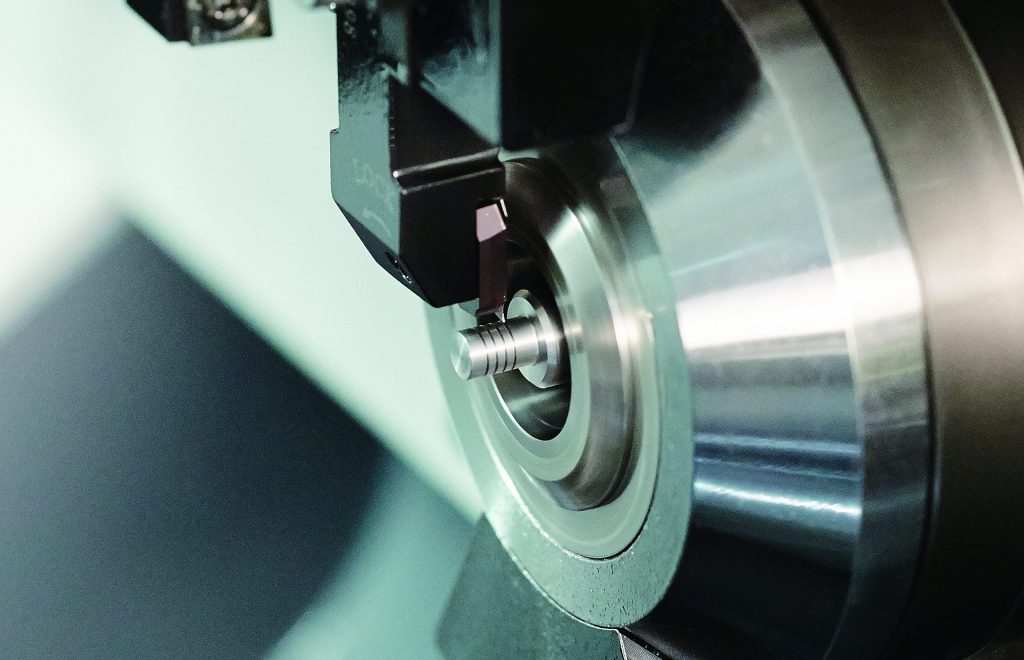

Kyocera Precision Tools expands the GBF grooving series for small parts machining to include new coolant-through (JCT-series) holders and a GL chipbreaker for larger groove widths. The new KGBF-JCT style holders feature internal coolant holes that direct coolant closer to the cutting edge from the top of the insert.

Kyocera Precision Tools expands the GBF grooving series for small parts machining to include new coolant-through (JCT-series) holders and a GL chipbreaker for larger groove widths. The new KGBF-JCT style holders feature internal coolant holes that direct coolant closer to the cutting edge from the top of the insert.

Achieve superior cooling action and excellent chip control when making small grooves. The coolant hole is designed to discharge an ample supply of high-pressure coolant to the cutting edge and provide stable chip curls.