Genior Modular VM-03 Machine Monitoring System

Genior Modular VM-03 Machine Monitoring System

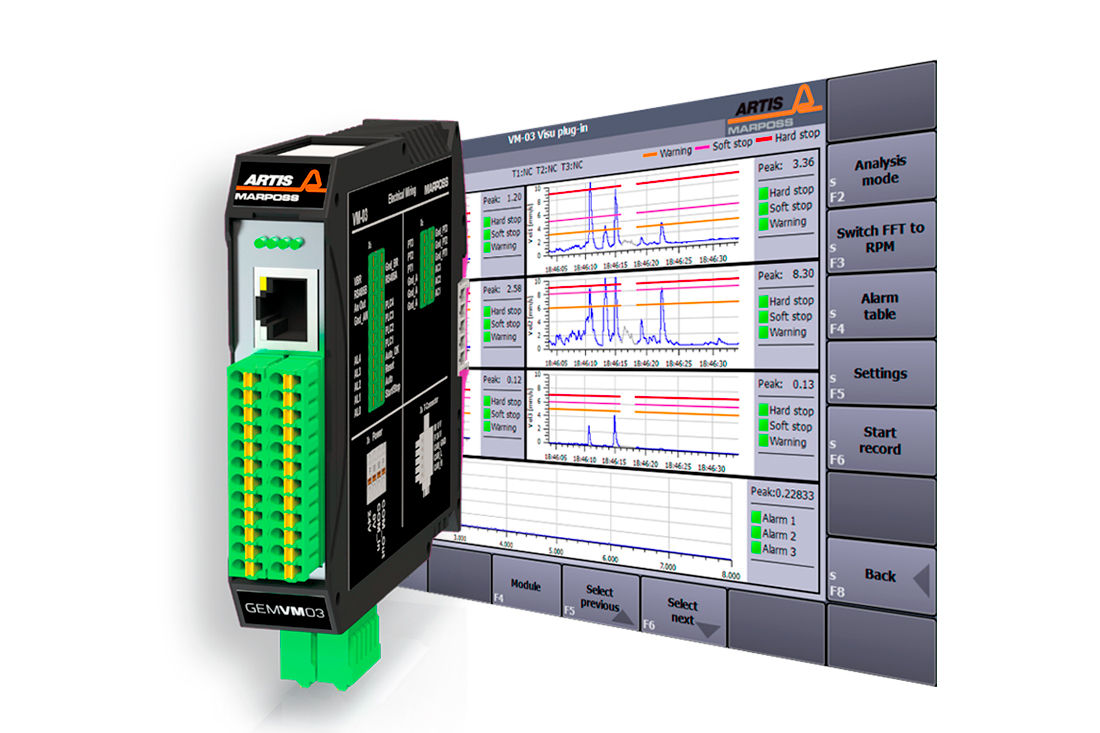

Marposs offers the Genior Modular VM-03 intelligent, module-based system for machine monitoring of a wide range of functions. The VM-03 provides predictive maintenance via vibration, gravity and temperature monitoring, condition monitoring, dynamic collision and crash detection and simple process monitoring. It can easily be integrated into machine tools, equipment or robots, as well as with the Genior Modular Tool and Process Monitoring solution.

Marposs offers the Genior Modular VM-03 intelligent, module-based system for machine monitoring of a wide range of functions. The VM-03 provides predictive maintenance via vibration, gravity and temperature monitoring, condition monitoring, dynamic collision and crash detection and simple process monitoring. It can easily be integrated into machine tools, equipment or robots, as well as with the Genior Modular Tool and Process Monitoring solution.

Bearing failures are responsible for 85% of spindle damages and 40% of bearing damages are due to collisions. Indications that there may be damages to the spindle can be recognized through a reduction of workpiece quality, an increase in bearing temperature, and through vibrations caused by bearing fatigue and raceway damage. The VM-03 aids in avoiding these issues by providing machine protection through detection of overload and potential crash; process monitoring to optimize cutting process parameters; and machine condition monitoring through predictive maintenance.

The VM-03 provides alarm output for acceleration in the form of warning, soft stop or hard stop; a temperature warning and a gravity value warning with registration of alarms occurring within +5 seconds of an event occurrence. All of this event data is recorded, illustrating operational processes and revealing any anomalies. For OEMs, access to this level of data can help protect from potential warranty claims.

The Genior system is a comprehensive, fully automatic solution with multi-sensor and multi-screen visualization capability to effectively monitor the machine, spindles, axis and the tool to optimize the cutting process.