H-811.F2 Compact Hexapod

H-811.F2 Compact Hexapod

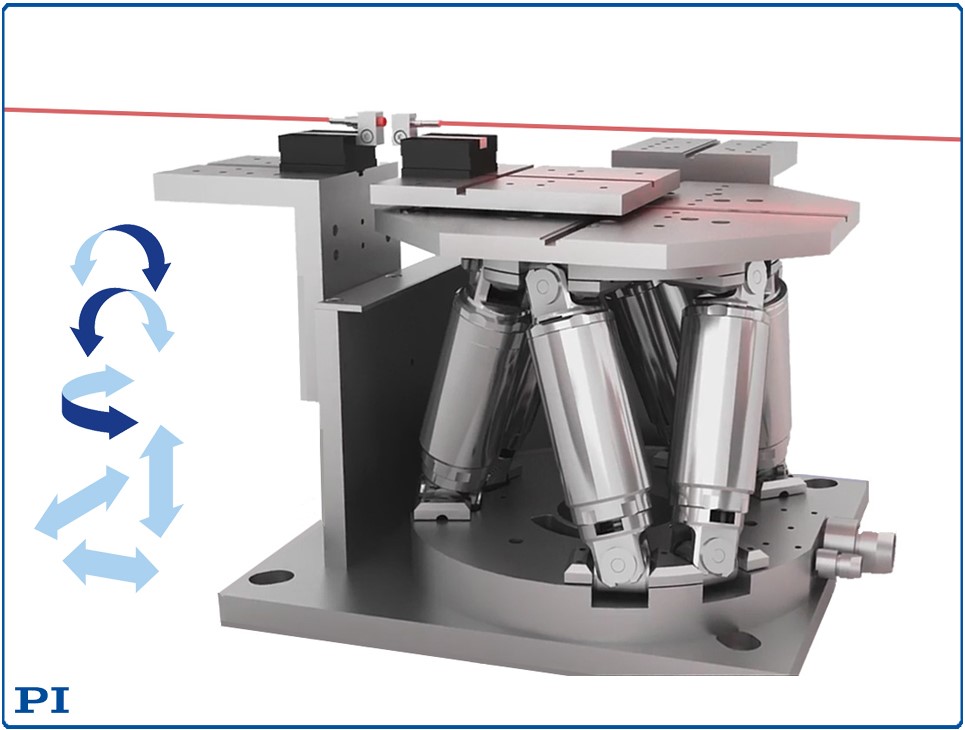

PI has added a high dynamics model to its range of compact hexapods. Designed for photonics alignment applications, the hexapod provides 6 degrees of freedom, actuator resolution of 5 nanometers and repeatability as good as 60 nanometers, while providing velocities to 20mm/sec. Sustaining loads to 5kg, the new H-811.F2 features a removable magnetic kinematic plate to accelerate workflow with different fiber optics components. Its compact size, large travel range of up to 34mm for linear motions and up to 42° for rotary motions, and a user programmable pivot point facilitate work with fiber optic and photonics components.

PI has added a high dynamics model to its range of compact hexapods. Designed for photonics alignment applications, the hexapod provides 6 degrees of freedom, actuator resolution of 5 nanometers and repeatability as good as 60 nanometers, while providing velocities to 20mm/sec. Sustaining loads to 5kg, the new H-811.F2 features a removable magnetic kinematic plate to accelerate workflow with different fiber optics components. Its compact size, large travel range of up to 34mm for linear motions and up to 42° for rotary motions, and a user programmable pivot point facilitate work with fiber optic and photonics components.

The hexapod is designed for industrial precision alignment applications with long-life brushless motors and low friction ballscrews and joints. A powerful controller with build-in multi-axis alignment routines makes the new hexapod an ideal tool for automatic alignment tasks.

Hexapods are 6 DOF positioning / motion systems that derive 6-axis movement (XYZ, pitch, yaw, roll) from actuators placed in parallel between a top and bottom platform. Available in a variety of sizes with bases ranging from 50mm to 1m and different load capabilities up to 2 tons, PI hexapods are an easy solution to complex multi-axis precision motion applications. PI hexapods come with state-of-the-art controllers and software tools based on 25 years of hexapod R&D, resulting in fast solution implementation to a plethora of applications from medical to photonics. All 6 axes can be commanded simply as Cartesian coordinates, and the center of rotation can be changed on the fly with a software command. Other advantages are the absence of friction and torque, caused by dragged cables.

Features and Advantages

- 6-Axis system (XYZ, Theta X, Y, Z)

- Travel ranges to 34mm linear / 42° rotary

- Strut resolution: 5 nanometers

- Load capacity to 10lbs

- Repeatability to 0.06µm

- Velocity to 20 mm/sec

PI has in-house engineered solutions with over 4 decades of experience working with customers to provide products that meet application demands, and can quickly modify existing product designs or provide a fully customized OEM part to fit the exact requirements of the application.