HBP-510/1208G Mitering Bandsaw

HBP-510/1208G Mitering Bandsaw

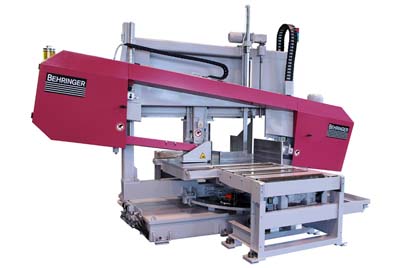

Behringer has introduced the new HBP-510/1208G mitering bandsaw for precision high speed cutting of large structural beams and profiles.

Behringer has introduced the new HBP-510/1208G mitering bandsaw for precision high speed cutting of large structural beams and profiles. With a cutting range of 47.2" X 20.0", and a bilateral miter of 30 degrees off of 90 degrees on both left and right side, the new saw is designed to meet even the most stringent demands in construction industries and the steel trades. The wide cutting range allows for even large structural beams to be cut at a 45-degree angle.

"The HBP-510/1208G saw has several design features that work toward assuring precise cuts and high throughput of large stock," said Richard Klipp, Behringer president. Klipp said that the "saw frame is torsion-resistant owing to a robust cast iron construction. This reduces vibrations during cutting and enables higher band tensioning."

Klipp explained that the vibration dampening design facilitates precision movement of the blade and results in tight tolerances. "The enhanced blade control," Klipp continued, "also allows very high downfeed rates which is important when trying to maintain high production rates on large structural materials."

The frame of the new Behringer saw is inclined 8-degrees. This optimizes the number of blade teeth which contact the material being cut. Too many teeth engaging the material can create a jagged or overly wide kerf. The angle of the HBP-510/1208G cutting blade, however, creates a clean efficient cut, especially when cutting large beams and profiles.

The HBP-510/1208G saw frame is designed with a rotary, swivel-action bearing for smooth miter angle adjustments. The mitering point is located at the intersection between the saw blade and the material support edge so that the measurement reference line never changes. The simple rotating action of the bearing lets operators make adjustments rapidly and achieve a high degree of accuracy in setting desired miter angles. A frequency controlled drive for fast, precise mitering angle adjustment is optional on the automatic saw model HBP-510/1208GA.

Powered by a 17.7 HP gear motor, the HBP-510/1208G utilizes a ball screw for precise downfeed control. The downfeed power/saw blade pressure is monitored by a servo-controlled cutting pressure sensing system. Sensor data is analyzed and the system continually makes precise adjustments to assure an optimum balance between blade feed and pressure. Operators can, therefore, maximize material feed rates without concern over overloading the blade. This results in sustained high output. Roller and pre-tensioned carbide guides permit smooth movement of the saw blade through the material.

The HBP-510/1208G saw frame height adjustment is automatic. Automated adjustment saves time by eliminating extra inches of movement each time new material is fed into the saw. The blade moves only the distance actually needed thereby minimizing non-cutting time before high-speed precision cutting resumes. A vibration dampening blade guide arm automatically adjusts to the cutting width of the material. The saw's vice jaws are heavy duty, designed to solidly clamp and align heavy structural beams.