HD and HDL Vises

HD and HDL Vises

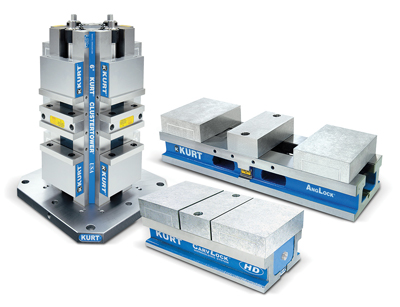

Kurt's HD and HDL Vises maximize workholding productivity.

Kurt's HD and HDL Vises maximize workholding productivity. These two-station vises are ideal for clamping parts of the same size or dissimilar size and can perform first and secondary operations simultaneously.

The HD and HDL series vises are new, patented designs providing more options for faster setups, larger workholding capacity, greater flexibility and precision to handle the broadest range of part configurations.

Kurt HD and HDL vises have new quick-change jaw feature and fewer components for faster job changeovers. With a half-turn of a hex key, the stationary jaw on these vises lifts off the vise. The jaw resets and self-aligns quickly without special tools. Spring preload design insures fast and easy loading of parts.

These new HDL two-station vises are extremely rigid delivering up to 7,460 lbs. of clamping force at 70 lbs of torque. They are designed on a 80,000 PSI ductile iron body with precision machined steel components and have a full 4 inch opening (6" vise) in each station using Kurt's standard hard jaw system. The manual model easily converts to hydraulic operation using a simple conversion kit.

The Kurt HD and HDL series is also available in Cluster Tower models providing more options for faster setups, larger workholding capacity, greater flexibility and precision. They are ideal for horizontal machining centers or vertical machining centers with indexable tables. These towers achieve workpiece immobility while damping cutter induced vibration.