Helislot

Helislot

The XNMU inserts are the original concept of double-sided inserts with 4 right-hand and 4 left-hand helical cutting edges for slot milling cutters. These inserts are made of SUMOTEC carbide grades, designed for milling alloy steel, ferritic and martensitic stainless steel, and cast-iron.

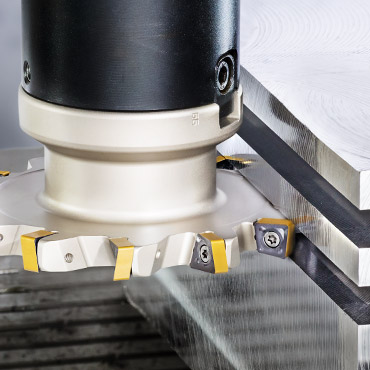

HELISLOT is a family of full slot milling cutters with square inserts that provide an effective and economical solution for machining slots and grooves. These cutters carry XNMU … inserts with a unique configuration.

The robust square double-sided insert features 8 (4 right-hand and 4 left-hand) helical cutting edges and a unique twisted upper and bottom surface. The inserts, when clamped on the insert's staggered teeth formation with alternating axial rakes, contribute to very stable cutting even under high chip loads. The twisted positive rakes create a smooth cutting action.

Due to the staggered teeth formation, positive rake, and rigid insert clamping the cutters assure high performance, reliability, and productivity.

The unique XNMU .. inserts are the original concept of double-sided inserts with 4 right-hand and 4 left-hand helical cutting edges for slot milling cutters. These inserts are made of SUMOTEC carbide grades, designed for milling alloy steel, ferritic and martensitic stainless steel, and cast-iron.

Features:

- Durable insert with 8 cutting edges.

- Staggered teeth with positive rakes.

- Rigid insert clamping.

- Bent shaped and quad hole for accurate positioning.

Advantages:

- Cost-effective.

- High productivity.

- Easy and smooth cutting.

Diameter range:

ETS

Metric: 40-48 mm

Imperial: 1.46 "

SDN

Metric: 100-200 mm

Imperial: 4.0-8.0"

FDN

Metric: 100-200 mm

Imperial: 4.0-8.0"

Insert size: 13 mm

Insert geometry:

- XNMU 130608PNN-MM

- XNMU 130608PNTN

- XNMU 130608PNN-PL

Grades

- IC808

- IC830

- IC330

- IC5400

- IC845

- IC810

- IC5100