High-speed Transfer

High-speed Transfer

STROTHMANN Machines & Handling reportedly has won the largest single contract for press automation in the Chinese market to date.

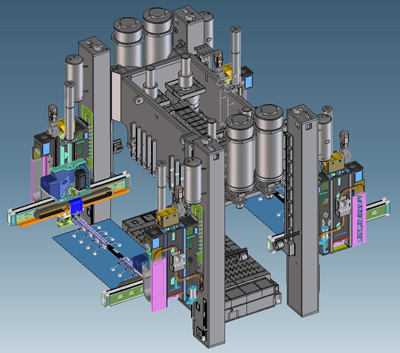

STROTHMANN Machines & Handling reportedly has won the largest single contract for press automation in the Chinese market to date. The contract from Shanghai Superior Die Technology Co., Ltd. is worth about 5 million euros. STROTHMANN supplies the complete parts handling consisting of a blank loader with fully automated tooling change, the new High Speed Transfer (HST), and parts unloading at the end of the new tandem press line. Employing linear servo technology, the HST is based on STROTHMANN's CompactTransfer, which was designed for press retrofits.

Siemens press simulation software is used to determine the safest, most efficient travel curve. At a 6 m distance between the press centers, up to 15 strokes per minute are feasible. The theoretical maximum acceleration is 25 m/s2; in the horizontal axis and 15 m/s2; in the vertical axis. The system is designed for blanks measuring up to 4,100 x 2,100mm, the rated payload is 120 kg (blank and tooling).

The HST is fastened to the press frame in travel direction. It is extremely compact and accessible, all modules are mounted above the floor, neither expansion tanks nor supply cables need to be installed in the press basement. This minimizes maintenance times. The freed-up space is used by tooling carts that automatically drive the toolings to the transfer point while the dies are changed.