HMC 6 Hybrid Motor Cable

HMC 6 Hybrid Motor Cable

All motors normally need two separate cables: one for the motor speed encoder and the other for the motor power supply. With the Hybrid Motor Cable Project called HMC 6, HEIDENHAIN has integrated the encoder lines into the power cable so now only one cable is needed between a synchronous motor and electrical cabinet.

All motors normally need two separate cables: one for the motor speed encoder and the other for the motor power supply. With the Hybrid Motor Cable Project called HMC 6, HEIDENHAIN has integrated the encoder lines into the power cable so now only one cable is needed between a synchronous motor and electrical cabinet. All the lines for the encoders, motors and brakes are now available in one cable, thus reducing hardware and associated costs.

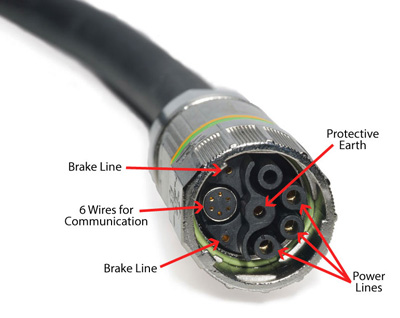

The connection of the new HMC 6 (Hybrid Motor Cable with 6 litz wires for measuring) single-cable to the motor is done with a special connector. For connection to the inverter, the cable is split into power connections and an encoder connector. This makes it compatible on the control side with all the same components as conventional cables.

The HMC 6 single-cable solution has been specially conceived for the HEIDENHAIN encoders with EnDat 2.2 interface with purely serial transmission; however, all other encoders with purely serial RS-485 interface can also be connected. This includes motor encoders for servo drives in the various sizes just as for linear and angle encoders used in direct drives. And of course it also includes encoders for Functional Safety up to SIL 3.

The HMC 6 single-cable solution offers a series of cost and quality improvements, both for the motor manufacturer and the machine tool builder:

No need to replace existing interfaces.

Allows smaller drag chains.

A smaller number of cables significantly improves drag chain flexibility.

Reduces mechanical requirements (flange socket on the motor, cable ducts in the machine housing).

Lower shipping and storage costs on cable and connector.

Installation is simpler and faster.

Lower cost of documentation.

Fewer service components are required.

The contour including the cable is smaller, making it easier to integrate the motor in the machine housing.