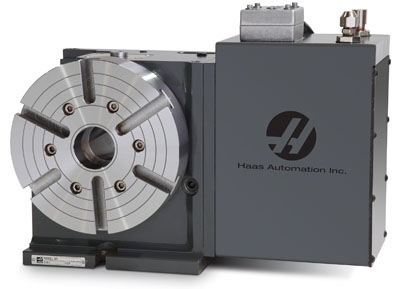

HRC210 Rotary Table

HRC210 Rotary Table

Adding a 4th-axis rotary table to a machining center is a proven way to boost productivity, reduce setups, and increase accuracy on multi-op parts. Adding a fast rotary table to a fast machine creates a high-speed package that slashes cycles times even further. The HRC210 from Haas Automation is a high-speed, cam-driven rotary table that provides cutting and indexing speeds up to 830 degrees/second.

Adding a 4th-axis rotary table to a machining center is a proven way to boost productivity, reduce setups, and increase accuracy on multi-op parts. Adding a fast rotary table to a fast machine creates a high-speed package that slashes cycles times even further. The HRC210 from Haas Automation is a high-speed, cam-driven rotary table that provides cutting and indexing speeds up to 830 degrees/second.

It provides 110 ft-lb (149 Nm) of spindle torque for synchronous 4-axis machining, and has a pneumatic brake that yields 134 ft-lb (182 Nm) of holding torque for stationary work. Indexing accuracy is +/-20 arc-sec, with repeatability of 4 arc-sec. The 8.27" (210mm) platter of the HRC210 has a center height of 6.000" (152.40mm), with a 2.00" x 1.91" deep (50.8mm x 48.5mm dp) pilot bore and 1.77" (45mm) through hole. Six radial T-slots simplify fixture and workpiece mounting, and both manual and pneumatic tailstocks are available for additional workpiece support.

The HRC210 is driven by a high-performance roller cam system that uses a high-torque servomotor to drive a globoidal cam meshing with cam followers equally spaced around the diameter of a roller gear. Needle bearings in the cam followers provide smooth contact with the cam, and a precision-engineered cam profile ensures accurate speeds and motion. Because the roller drive is preloaded during assembly, the system yields high stiffness, high torque, and high speeds, while providing low wear characteristics and reducing maintenance.