HS Flex Handling System

HS Flex Handling System

Hermle's newest automation solution is the HS Flex. Attractively priced, the HS Flex handling system is a powerful and compact automation tool, the company reports.

Hermle's newest automation solution is the HS Flex. Attractively priced, the HS Flex handling system is a powerful and compact automation tool, the company reports.

"We are excited to bring this solution to the marketplace," said Manuel Merkt, vice president of operations at Hermle North America. "Despite not yet being marketed, several units have already been sold, which clearly demonstrates the economic benefits that automation represents in advanced manufacturing."

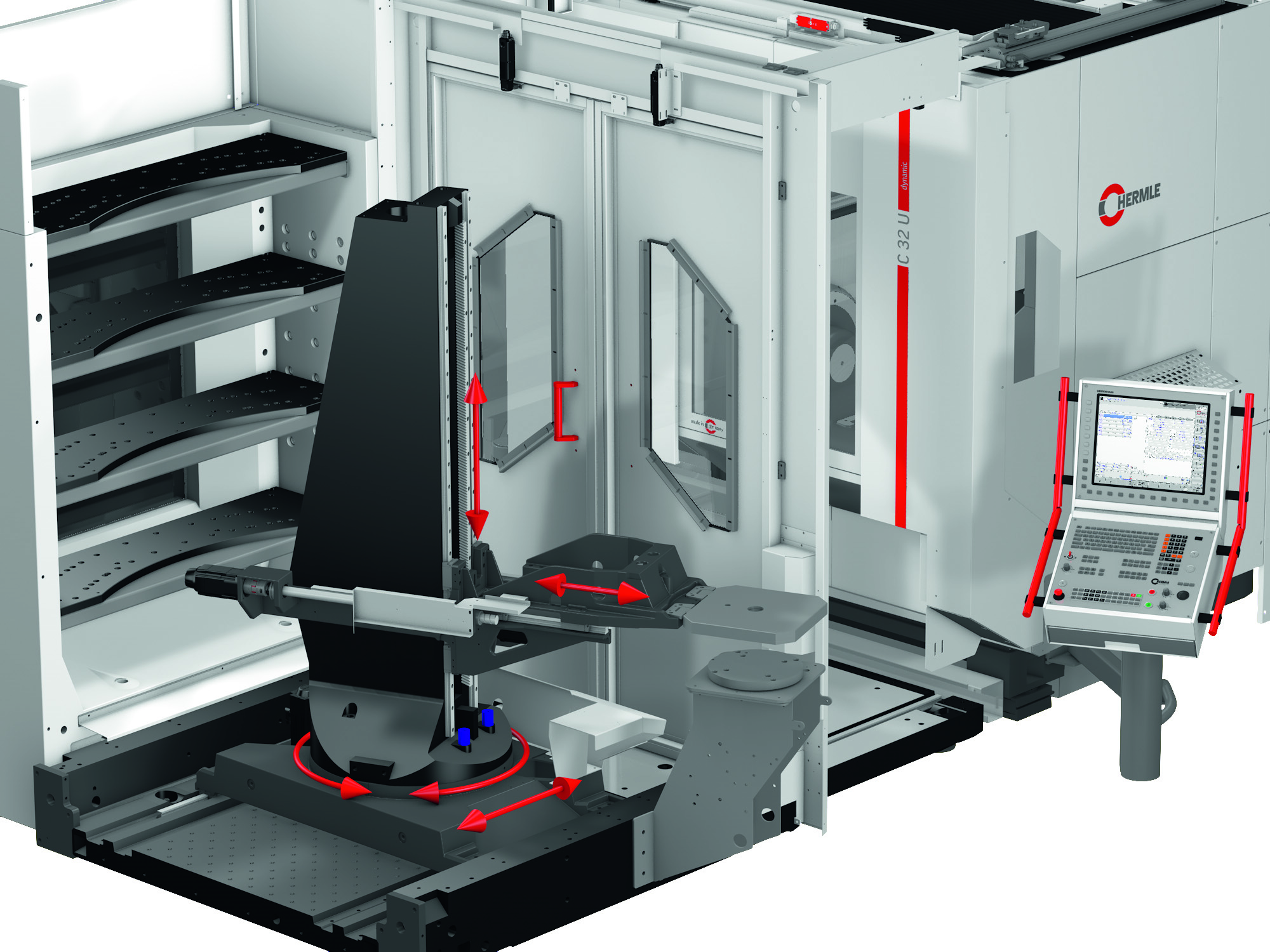

The HS flex handling system is designed to fit 3-axis and 5-axis Performance Line machining centers (C 250 and C 400), as well as to High Performance Line models (ranging from the C 12, C 22, C 32 up to the C42).

The HS flex handling system is made up of several components, which are supplied as one complete unit, only the workpiece storage modules are installed and adjusted on site. As a result, the entire installation is available in a short time, allowing the end user to start machining without delay.

The flat mineral casting bed, on which the three axes of the handling unit are operated, offer ergonomically and convenient access for the operator. The two double-leaf doors, which have proven benefits in Hermle's robot systems, provide a twofold function: During a pallet change procedure, they prevent access by the operator, and during machining of the workpiece, they provide access to the working view position and working area while preventing access to the handling unit.

The rotary, lifting and linear axes of the handling unit, enable precise movement of the heavy workpieces up to 450 kg, including the pallet, between the setup station, storage modules and the machining center's working area. It is possible to handle pallets of up to 500 x 400 mm. To minimize potential operator error, the maximum workpiece height is queried beforehand at the setup station, preventing workpieces with dimensions beyond specified from being fed in.

Another key function of HS Flex is the storage module. One module is installed as standard, and the adaptation of a second module is optional. The modules are structured as a rack, offering maximum customization in the pallet/workpiece arrangement. Up to four rack shelves can be ordered with a total of up to 20 pallet storage spaces per module, providing up to 40 pallet storage spaces when two modules are installed. The storage arrangement can be defined quickly and easily using a specially developed storage generator, which tests both the permitted weights and dimensions.

The HS flex, pallet changer and RS 05 robot system are all controlled and managed using the proprietary Hermle Automation Control System (HACS). HACS allows for smart order management, which intuitively aids the operator in their daily business via a software solution that can be operated by means of a touch panel. When combined with the Hermle Information Monitoring System (HIMS), which displays machine status in real time and can be shown on any tablet, desktop or smartphone, these two software tools are collectively a cornerstone of Industry 4.0-capable deployment of Hermle machining centers.