Contact Details

Water is not only the elixir of life but has also established itself in industrial production for cooling, cleaning, or as a solvent. Furthermore, waterjet cutting is recognized as a reliable alternative to conventional cutting processes. Extremely smooth cut edges without thermal stress, post-processing, and minimal kerfs are just a few of the advantages of the cutting process for a wide range of materials and applications. A key factor for efficient processes is the waterjet nozzles. With the new HyproJET portfolio, CERATIZIT sets new standards for quality and durability.

Waterjet cutting works as simply as it is effective: the cutting head directs a fine jet of water at high pressure of up to 6,000 bar, a jet diameter of 0.38 to 1.02 millimeters. In this stress-free cutting process, the material particles close to the surface are cut off without any heat being introduced into the material. This process is an optimal solution for temperature-sensitive and thick materials with complex geometries.

Three versions for all requirements

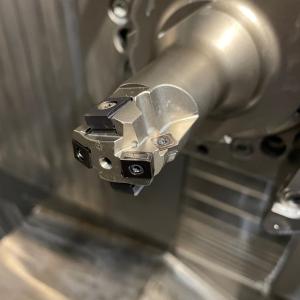

The possibilities of water jet cutting are incredibly diverse, which means that it can be used by a wide range of users for a wealth of different requirements. “We developed our HyproJET range with three standard water jet nozzles to meet these needs: narrow hole tolerances, perfect cutting and radial run-out accuracy ensure precise working results,” says Mesut Goksu, Segment Account Manager at CERATIZIT. The HyproJET X6 is a powerhouse with improved flow of abrasive material and air in the nozzle and a special design for cutting even the most difficult materials. For standard applications, CERATIZIT’s range includes the HyproJET P6, which stands out in particular thanks to its optimal price-performance ratio. For anyone looking for high-quality results at a low price, the affordable S3 standard water jet nozzle is the perfect choice. All nozzles are suitable for modern cutting head systems and support automatic centring during assembly.

Optimized wear protection defies abrasives

For some materials to be machined, water alone is not sufficient as a cutting material. The system then mixes an abrasive, such as garnet or corundum, into the water jet. Particularly with demanding materials such as steel, stone, glass, or composites, abrasives are very efficient helpers. But as much as they support the cutting process, they are not without disadvantages, explains Mathieu Schellenberger, project manager in product development at CERATIZIT: "They put a lot of strain on the focusing tubes due to erosion. Therefore, when redesigning the HyproJET products, we further improved the wear protection." For this purpose, special carbide grades were used, as a result of which the HyproJET nozzles last for a long time even at pressures of up to 6,000 bar, and achieve very high cutting qualities.

Carbide solutions from a single source

CERATIZIT takes care of all process steps from the carbide powder to the ready-to-use solution, resulting in consistently first-class product quality, precision, and best performance. In addition to the comprehensive waterjet nozzle portfolio, the company produces various mixing chambers made of special carbide grades to meet the different wear mechanisms within these chambers. Pistons for high-pressure pumps, spray discs, collecting cups, inlet guides, wear plates, throttle shields, and inlet pipes are also offered.

To ensure that the HyproJET nozzles reach the customers safely, CERATIZIT has also changed a few things in terms of packaging: For example, the company relies on plastic sleeves that optimally protect the waterjet nozzles, but at the same time are particularly sustainable. They are made of 100% recycled plastic, so-called PCR plastic (Post Consumer Recycled), which reduces CO2 emissions by at least 60% compared to conventionally produced plastic.

New portfolio well received

Before a new product is launched on the market, it undergoes thorough and intensive testing. For this purpose, CERATIZIT works together with waterjet cutting experts who have used the HyproJET portfolio for industrial use. "The reactions exceeded our expectations. Because when we hear that even experienced professionals rave about the service life and cutting qualities of the HyproJET X6, we have achieved our goal which is to develop a product that makes daily work more efficient and, at the same time, meets the highest quality standards," Mesut Goksu sums up.

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.

- waterjet cutting

waterjet cutting

Fine, high-pressure (up to 50,000 psi or greater), high-velocity jet of water directed by a small nozzle to cut material. Velocity of the stream can exceed twice the speed of sound. Nozzle opening ranges from between 0.004" to 0.016" (0.l0mm to 0.41mm), producing a very narrow kerf. See AWJ, abrasive waterjet.

PRODUCTS

PRODUCTS