igubal Spherical Balls

igubal Spherical Balls

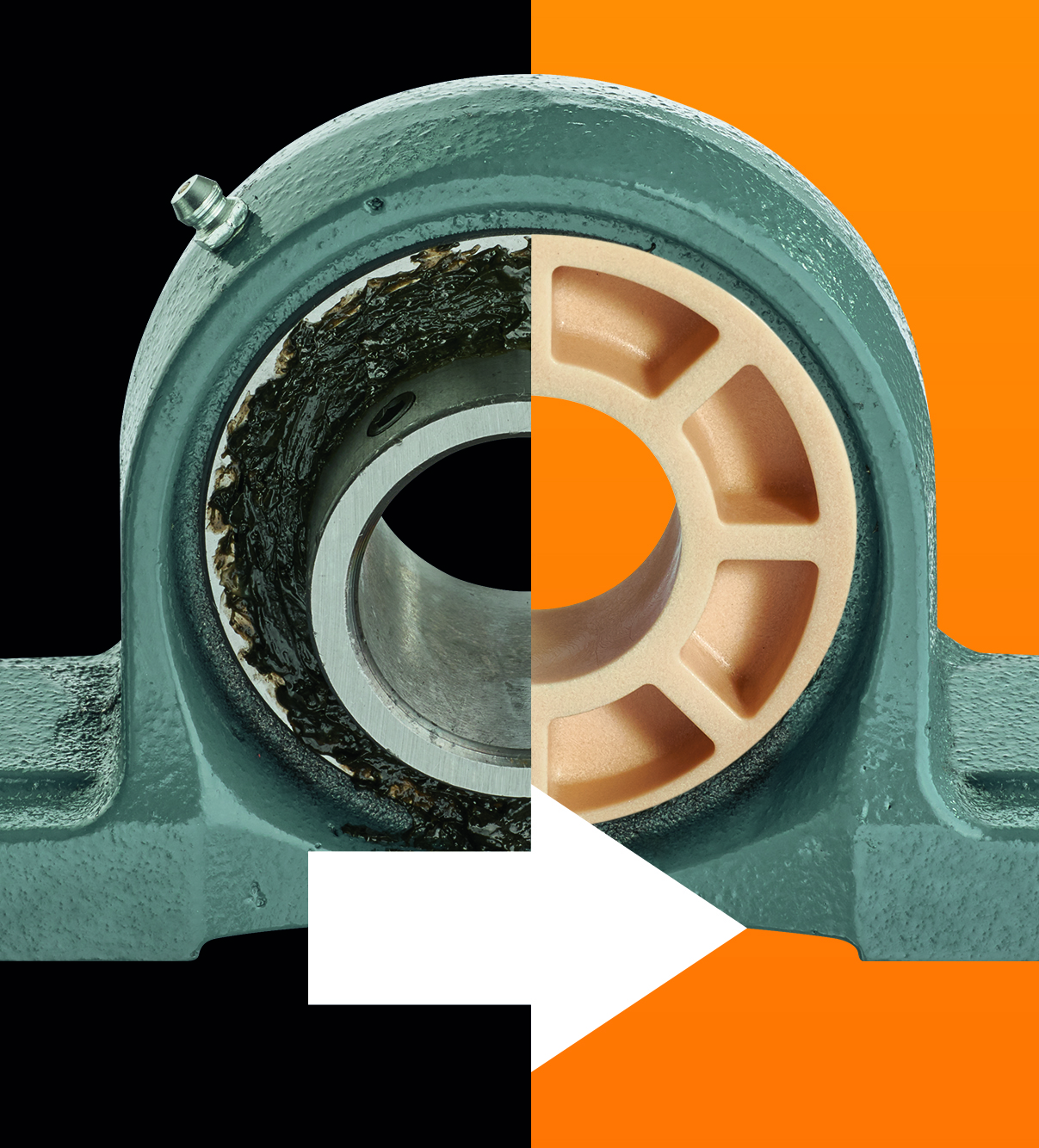

Pillow block and flange bearings are commonly used in construction machines and conveyor systems, therefore they are often exposed to dirt and dust. This exposure to foreign debris creates extreme loads that the bearings must endure. To withstand these harsh scenarios, metallic bearings must be regularly maintained and lubricated. With the new igus spherical balls made of the high-performance plastic iglide J, users can now rely on a self-lubricating and maintenance-free solution.

Pillow block and flange bearings are commonly used in construction machines and conveyor systems, therefore they are often exposed to dirt and dust. This exposure to foreign debris creates extreme loads that the bearings must endure. To withstand these harsh scenarios, metallic bearings must be regularly maintained and lubricated. With the new igus spherical balls made of the high-performance plastic iglide J, users can now rely on a self-lubricating and maintenance-free solution.

The narrow igubal spherical balls are developed directly from the injection-molding process and can be inserted into existing metallic pillow block and flange bearing housings within seconds. Due to the absence of external lubricants, dirt and dust cannot adhere to the bearings, further minimizing wear. This also eliminates machine downtime.

The long service life of the igubal spherical balls was demonstrated in a biomass chipper. Where metal bearings on the conveyor belt of the chipper had to be lubricated monthly, retrofitted flange bearings with the igubal spherical ball stayed wear-resistant for over a year, without lubrication or maintenance.

The spherical balls made of iglide J are not only cost-effective, but also have a very low coefficient of friction in dry operation. The material absorbs only a small amount a moisture, so they are suitable for outdoor use. They are suitable for use in chemically-exposed applications, such as agricultural technology, due to the chemical-resistance of the plastic. Soft shafts are also the ideal mating surface for the material to display its advantages.

The igubal spherical balls are currently available in six dimensions for housing number 204-210. As an alternative to injection molding, igus offers customers the option of machining spherical balls from their desired material from the iglide bar stock product range.