iLimitS CNC Software Option

iLimitS CNC Software Option

FANUC Factory Automation (FANUC FA America) introduces iLimitS CNC software option that provides machine process monitoring including spindle load, spindle speed and up to 4 coolant flow devices.

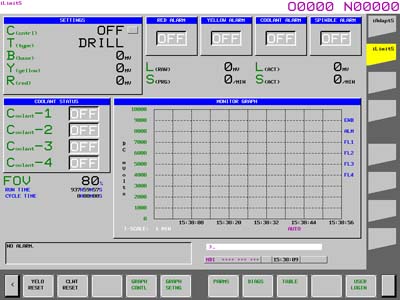

FANUC Factory Automation (FANUC FA America) introduces iLimitS CNC software option that provides machine process monitoring including spindle load, spindle speed and up to 4 coolant flow devices. iLimitS monitors the process and protects the machine, parts and fixtures. If an abnormal process is detected, a warning can be displayed or an alarm will stop the process before damaging the machine. iLimitS is a cost effective solution made by FANUC for FANUC CNCs. It is seamlessly integrated into the CNC, so no external PC is required.

iLimitS process monitoring includes real-time monitoring of the spindle load, spindle speed and coolant flow from up to 4 different coolant sources. "iLimitS provides real-time monitoring of the machine and part to protect them from abnormal conditions," states Paul Webster, Engineering Manager at FANUC FA America.

Monitoring parameters are provided so that warning and alarm thresholds have a time delay before alarm and tolerances can all be set. iLimitS samples the process at a rate of less than 48ms; this provides superior resolution and reaction time for abnormal process detection. The sampled data is compared to the user defined threshold settings and when a violation is detected, the FANUC machine interface (PMC) is signaled to stop the machining process. In the situation of an alarm, the operator must clear the condition before machining is allowed to resume. A macro interrupt mode is also provided that allows for a customer designated macro program to execute in the event of a monitoring alarm condition. This allows the customer to take corrective actions programmatically or even send a text report of the condition for traceability.

iLimitS is set through parameter settings and activated by macro calls within the part program, this allows for a high degree of flexibility for the operator and programmer. "LimitS is seamlessly integrated into the FANUC CNC and provides a high degree of operational flexibility from basic spindle abnormal load monitoring to load, speed and coolant monitoring with macro interrupt," states Webster.

Since iLimitS is embedded into the CNC itself, no external sensors are required when using a FANUC serial spindle interface. For analog spindles and coolant monitoring, external sensors can be added as needed for the application.

iLimitS meets the stringent GE Aviation P11TF12 specification requirements. Additionally, iLimitS supports a wide range of applications from simple spindle loading monitoring to extensive process control and traceability. The intuitive user interface screens are integrated seamlessly into the CNC and provide access to all setup and monitoring information without the need for an external computer or extra hardware.