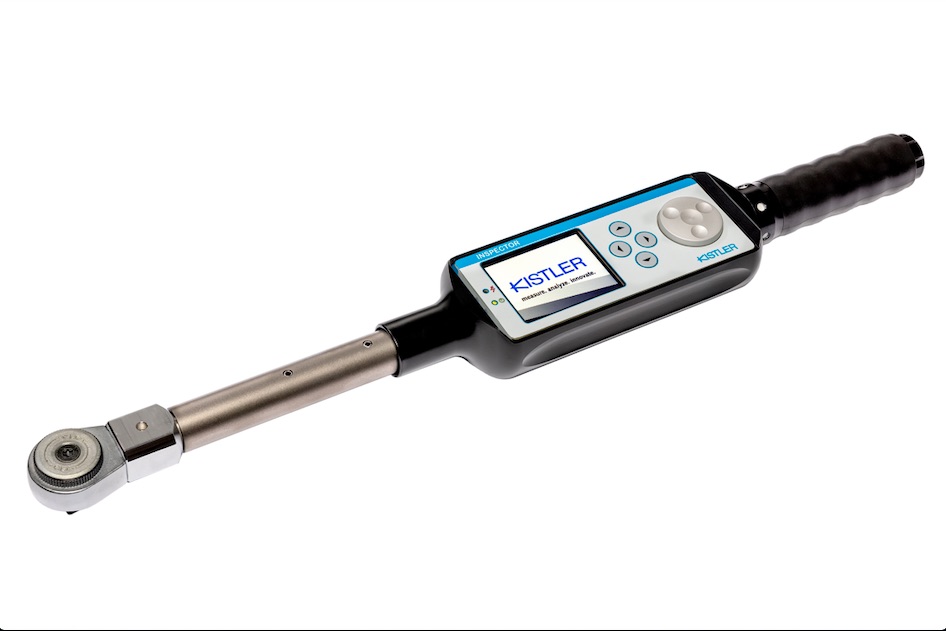

INSPECTOR Torque Wrench

INSPECTOR Torque Wrench

The INSPECTOR meets a requirement that is especially important in the automotive and vehicle manufacturing industry: quality assurance compliant with the VDI/VDE guideline after the fastening process is completed. The new torque wrench also offers an advantage that was never available on the market until now: an interface with the CEUS and testXpert software applications for evaluation and archiving.n

Kistler is expanding its range of inspection systems for fastening technology by introducing the new INSPECTOR torque wrench. Thanks to this easy-to-handle device with its display/measuring unit, users can carry out process capability tests on bolted joints for evaluation and documentation of fastening processes under series production conditions in a matter of seconds. The INSPECTOR meets a requirement that is especially important in the automotive and vehicle manufacturing industry: quality assurance compliant with the VDI/VDE guideline after the fastening process is completed. The new torque wrench also offers an advantage that was never available on the market until now: an interface with the CEUS and testXpert software applications for evaluation and archiving.

Bolted joints, which come in a wide variety of designs, play an essential part in industrial production as a safe and verifiable method of connecting components. In the automotive industry, for instance, bolted joints are used for all important connections on wheels, axles, airbags, safety belts and brakes, to name only a few examples – and most of these joints are relevant to safety, so they require special attention as regards documentation.

This sets high reliability requirements for the inspection systems that are used in research, production and – above all – quality assurance. Further tightening has become firmly established as a testing method in recent years. Shorter cycle times are making it increasingly difficult to perform tests directly after assembly. But with the further (or carry-on) tightening test method, a torque wrench is used to continue tightening the joint by a defined further rotation angle after it has already been fastened, and the resultant torque is then measured. Thanks to recording and statistical evaluation of the fastening curve, suitable methods can be used to determine whether the bolted joint was produced in a controlled and capable process.

Handheld electronic tool

"The new INSPECTOR electronic torque wrench from Kistler provides users with a high-performance tool for process capability tests," according to Wilfried Blechmann, Head of the Fastening Technology Business Field at Kistler. "This is a compact, easy-to-operate tool that combines precise measurement technology with a very comfortable high-quality user interface. It will help users to assemble bolted joints reliably and provide proof of process capability in compliance with VDI/VDE 2645 Part 3," Blechmann continues. Another benefit: the digital measurement signals acquired from the INSPECTOR during testing can be evaluated and archived with the CEUS and testXpert software applications.

Connectivity allows evaluation and archiving

For this purpose, the database-supported CEUS software from Kistler handles all the tasks required for documented inspections of the fastening process: parameterization via CEUS allows operators to define tests according to customer-specific, standardized or guideline-based requirements, with free configuration of the fastening points. For more extensive documentation and evaluations, the measurement data can be transferred to the CEUS software with its varied range of options for statistical evaluation. CEUS also makes it easier to plan the testing schedule, and users benefit from software support as they process their workload with the help of stored testing tasks (known as "routes") that are transferred to the INSPECTOR. Inspection reports and data export provide plenty of flexibility, too: an editor allows users to integrate results, tables and graphics as well as freely definable parameters into an inspection report according to their individual requirements. All data obtained can also be forwarded automatically to higher-level software platforms via an export interface. And in addition, the testXpert software used by Kistler makes it possible to transfer the measurement data from the new torque wrench to the evaluation software so that advanced evaluations can be performed.

"Kistler's portfolio of inspection systems for bolted joints is already extensive, and now the addition of the INSPECTOR gives customers an even wider choice of fastening technology solutions," Blechmann notes. "A varied range of inspection systems, the unique interface offered by the new torque wrench for connection to CEUS and testXpert software, and specific services: factors that add up to a comprehensive offering, precisely in line with customers' requirements for quality assurance in fastening technology. Users can take advantage of benefits that will help them to meet the growing requirements for process capability, traceability, product liability and efficiency."