Contact Details

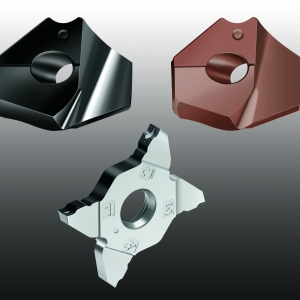

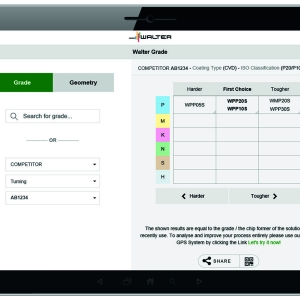

Walter has announced a new addition to its product line: the WXN15 coated grade for machining ISO N materials. Responding to the growing use of aluminum in the automotive and aerospace industries where it is valued for its ability to save weight, and in general metalworking where it can speed machining in a range of applications. Walter is responding with products like the WXN15 coated grade as well as other cutting tool inserts that capitalize on this growing trend.

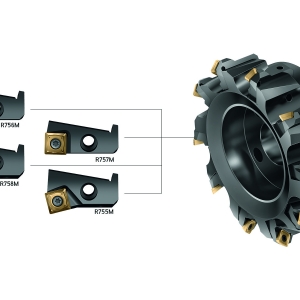

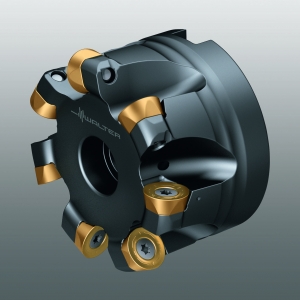

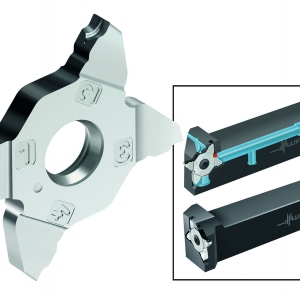

These WXN15 grade coated inserts are all introduced with a highly positive shaped geometry, which is particularly effective in machining ISO N materials. When used in advanced cutter bodies like the new Xtra·tec® XT M5468 button insert milling cutter, with G88 geometry, this also increases productivity when performing machining operations on deep shoulders with excellent chip removal.

These WXN15 grade inserts are available in 77 varieties of insert shapes, sizes, and varying geometries, to fit all of the most popular Walter milling families. WXN15 coated grade inserts can be used for copy milling, face milling, ramping, pocket milling and circular interpolation milling.

Though engineered for excellence in aluminum machining, most inserts of this WXN15 coated grade are also effective on other non-ferrous materials as well as some steels, stainless steels, cast iron, and even materials with difficult cutting properties, including hard machining.

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- interpolation

interpolation

Process of generating a sufficient number of positioning commands for the servomotors driving the machine tool so the path of the tool closely approximates the ideal path. See CNC, computer numerical control; NC, numerical control.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

PRODUCTS

PRODUCTS