Jetstream Tooling High-Pressure Coolant Technology

Jetstream Tooling High-Pressure Coolant Technology

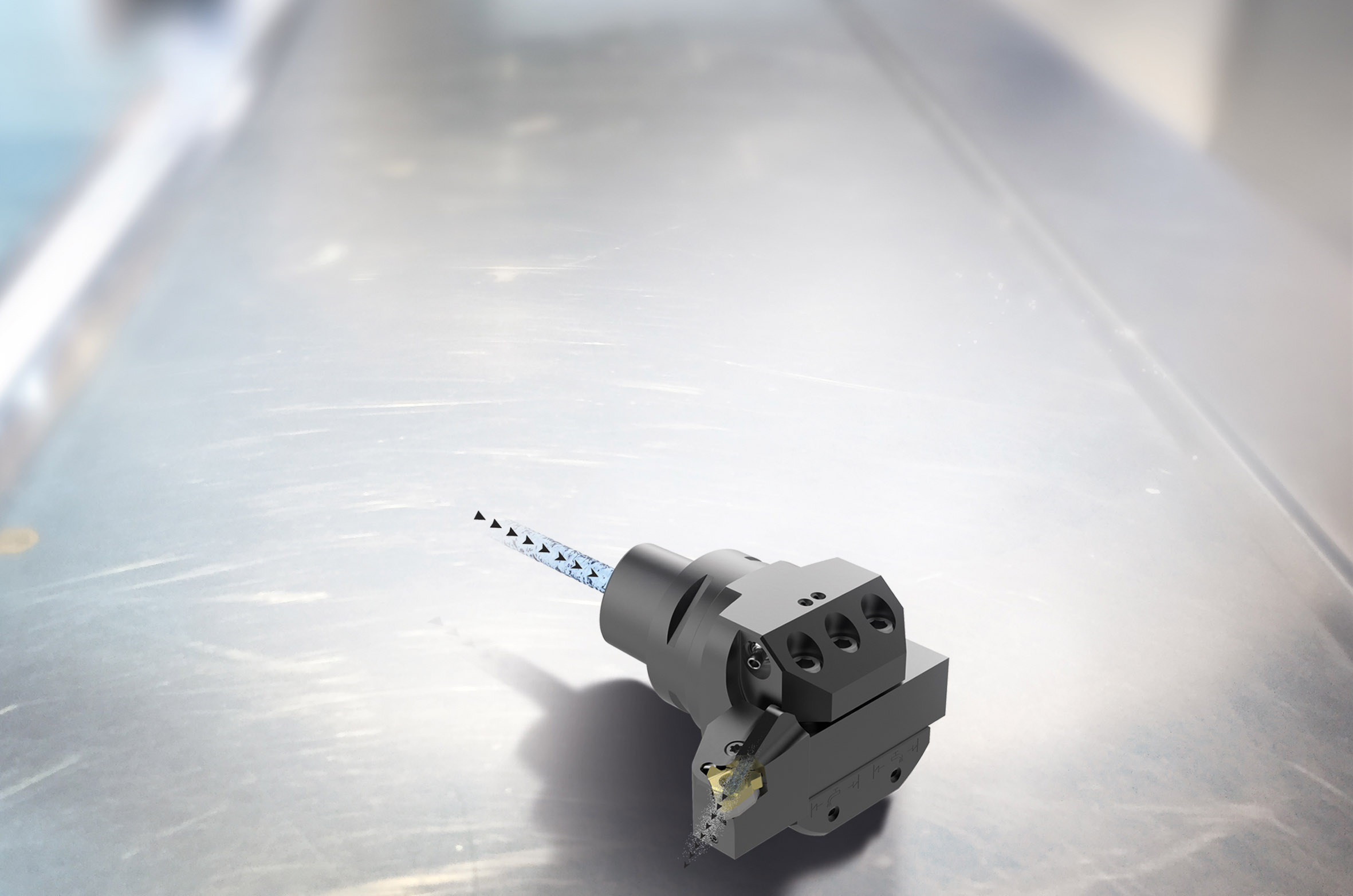

Seco Tools has introduced Jetstream Tooling high-pressure coolant technology for threading shank holders. The new range includes shank holders for external applications, boring bars for internal applications and GL-heads for use with Seco Steadyline boring bars.

Seco Tools has introduced Jetstream Tooling high-pressure coolant technology for threading shank holders. The new range includes shank holders for external applications, boring bars for internal applications and GL-heads for use with Seco Steadyline boring bars.

The Jetstream Tooling thread turning holders deliver a concentrated high-pressure jet of coolant through a hose connection for up to 275 bar/3,988 psi coolant inlets to the optimum position close to the cutting edge. Unlike flood coolant, high-pressure coolant can penetrate the heat vapor barrier that develops on a cutting tool and workpiece in the cut zone. This Jetstream technology also makes it possible to guide or steer chips away from the cut and increases tool life, even with minimum coolant pressure.

For parts made from titanium or similar materials, Jetstream Tooling technology is capable of breaking the tough threading chips to increase tool life. When threading steel and stainless steel, the improved chip control of the new thread turning tools allow for potentially 30 percent to 60 percent higher cutting speeds without compromising thread surface quality.

Jetstream Tooling thread turning holders are available in 16 external, 28 internal and 14 GL-head types in insert pocket sizes 16, 22 and 27.