KCI/KBI 1300 Series Inductive Rotary Encoders

KCI/KBI 1300 Series Inductive Rotary Encoders

Each lightweight KCI 1319 / KBI 1335 encoder includes a 25 mm hollow shaft and inductive scanning technology that makes it insensitive to contamination and magnetic fields. The encoder communicates using the high speed EnDat 2.2 interface which also allows for additional information, such as temperature or diagnostics, to be communicated as well.

With its small dimensions and high reliability, HEIDENHAIN's new KCI/KBI 1300 series of inductive rotary encoders are made specifically to support compact servomotors for collaborative and service robots.

First presented at the international virtual trade show SPS in November of 2020, these new KCI 1319 / KBI 1335 measurement feedback devices are now available and are proving to be of great interest to those in this ever-growing market.

Each lightweight KCI 1319 / KBI 1335 encoder includes a 25 mm hollow shaft and inductive scanning technology that makes it insensitive to contamination and magnetic fields. The encoder communicates using the high speed EnDat 2.2 interface which also allows for additional information, such as temperature or diagnostics, to be communicated as well.

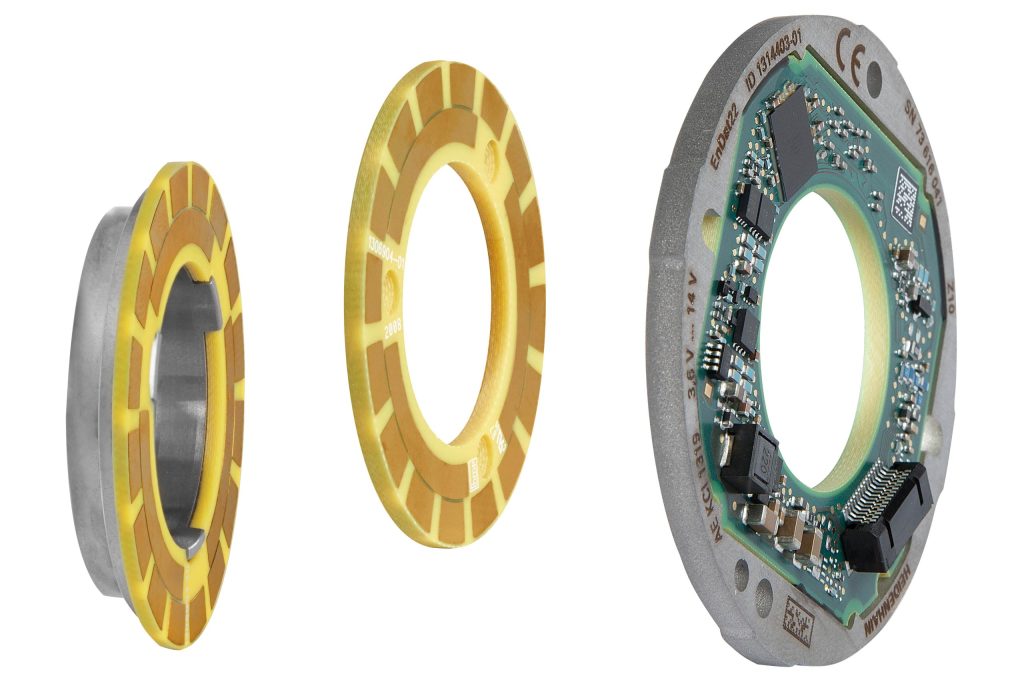

In structure, these rotary encoder kits consist of a scanning unit and a rotor. The rotary encoder can be offered in two different versions. One variant consists of a graduated disk that is directly screwed onto the mating shaft; the other variant is a disk/hub assembly that is press-fit onto the mating shaft.

Benefits of the encoder in applications with collaborating robots:

• Contamination-resistant inductive circumferential scanning

• Compact height

• Connection to large hollow shafts with 25 mm, compared to the external dimensions

• Large mounting tolerances

• No calibration run for increased accuracy necessary as is the case with the competitor RLS

• Insensitivity to magnetic fields of up to 30 mT

• Connection of an external temperature sensor

• Purely-serial EnDat 2.2 interface / functional safety planned